- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Annual Publication "Micromeritics"

- Industrial Property Rights

- Journals and Books

- Technical Information

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- About Us

- Technical Information

- Details of Dedusting Technology

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Annual Publication "Micromeritics"

- Industrial Property Rights

- Journals and Books

-

Technical Information

- Summury of Powder Technology

- Details of Millling technology

- Details of Classification Technology

- Details of Mixing/Blending Technology

- Details of Particle design Technology

- Details of Agglomeration Technology

- Details of Drying Technology

- Details of Dedusting Technology

- Details of Measuring Technology

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Details of Dedusting Technology

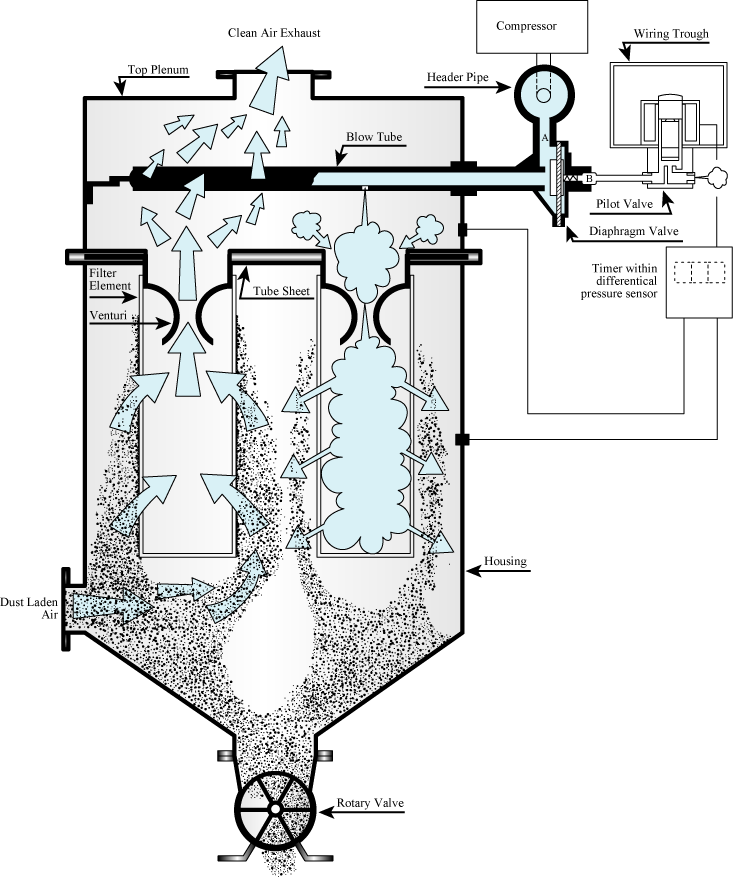

In many operations that involve handling powders, the powder is carried in a gas or liquid stream. Therefore, in order to extract the powder, it must be separated from these fluids, and this operation is called dust collection. Among these, the device that collects the dust with a filter like a vacuum cleaner is called a filtered dust collector (Bag filter).

Principle of the equipment

As shown in the structural diagram of the machine, an inlet for dust-containing air/gas is provided on the side of the housing, and the dust-containing air/gas flowing in from here reaches the outer surface of the filter inside the housing, where the powder/dust is collected on the outer surface of the filter, and only the filtered and cleaned air/gas passes through the filter and is exhausted from the exhaust port through the top plenum.

The filter is attached to the tubesheet inside the machine, and there are two types: a molded type and a sewn type that uses fittings (retainers) to hold the cylindrical shape.

The powder and dust collected on the outer surface of the filter are removed by the pulse jet backwash mechanism, fall into the hopper at the bottom of the housing, and are discharged out of the machine through the discharge machine (rotary valve, etc.).

Pulse-jet cleaning mechanism

.jpg)

The cleaning area is moved at predetermined intervals.

The pulse-jet cleaning mechanism efficiently and continuously removes powder and dust collected on the outer surface of the filter to eliminate clogging of the filter and ensure stable and continuous operation.

The mechanism of the pulse jet cleaning mechanism consists of a header pipe, diaphragm valve, pilot valve, blow tube, venturi, and timer (control panel) mounted on the top plenum.

Compressed air/gas (standard pressure: 0.4-0.7MPaG) supplied to the header pipe passes through the diaphragm valve and is ejected from the blow hole in the blow tube by the instantaneous action of the pilot valve. At this time, the Venturi effect causes the air and gas in the surrounding area to be entrained and injected all at once into the filter, causing the filter to vibrate violently and ensuring that the powder and dust adhering to the outer surface of the filter are removed.

In order to minimize fluctuations in the airflow through the dust collector, each filter is cleaned once every 1 to 3 minutes, and a cyclic system is adopted in which no more than 30% of all filters are cleaned at the same time.