- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Annual Publication "Micromeritics"

- Industrial Property Rights

- Journals and Books

- Technical Information

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Safety Booth HSB

Safety Booth HSB

Summary

The Safety Booth HSB is the containment system which provides both operator protection and product protection (protection of product from contamination by foreign materials). It can be used for the processes of grinding, weighing, repacking, filling, discharging, measuring, and overhauling in R&D or production process. It minimizes the possible risk of scattering of chemically hazardous substances (dangerous/toxic material). Functionally, it is sometimes called a downflow booth. Generally, in processes where chemically hazardous materials are being handled, the use of a local nuisance dust venting system and operator protection is done with personal protection equipment (goggles, dust masks etc.). Local venting system alone makes it difficult to contain dusts and therefore there is high risk of operator health damage by inhalation of dusts in the air.

By controlling the air stream, it is possible to control the dust flow, and to protect the operator, as well as preventing the dust spreading to other areas.

In this system there is a vertical air flow from top to bottom of the HSB. This ensures that dust is taken downwards. The air and dust are then passed through a filtration unit. The cleaned air is then recirculated via the ceiling of the booth or in the case of single pass booths is exhausted.

Principle

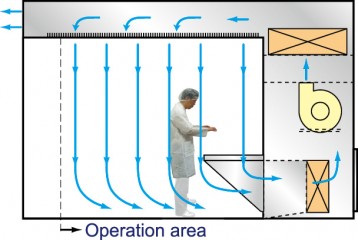

Fig.1 Air flow in Safety Booth

The air pushed from the blower passes HEPA filters and becomes clean, with virtually no dust and then flows downward from the special diffuser forming a vertical laminar flow. This airflow prevents scattering of hazardous substances around the breathing area of the operator, and pushes down the dust generated from powder processing operations and realizes operator protection. Cleaned air prevents contamination from foreign material therefore realizes the product’s protection. Dust generated in the system is introduced into the lower suction port via airflow and filtered (Fig.1). By keeping the system under negative pressure with the control of the air, dust generated in the system is prohibited from scattering outside, thus high operational efficiency is realized.

Features

Flexible design is possible:

Most suitable system can be presented meeting individual operational conditions.

Countermeasures for Nano Risk:

Fig. 2 Air velocity measurement

Captures Nano size particles and offer safe operational space (Fig.2)

Supply comfortable operational space:

Controls the temperature and humidity of operational space by combining air conditioning system.

Realizes OEL 1 below a few micro gram/m3:

Realizes the containment level as high as an isolator, by combining a screen with glove ports (Fig.3)

(OEL: occupational exposure limits, i.e. permissible degree of hazardous substances exposure on operators)

Safe filter replacement:

By bag-in-bag-out method, filter replacement can be done without direct contact of the dust laden filter.

Energy saving specification:

With selection of functions such as automatic lighting, temperature control and airflow control, utility cost can be reduced.

Fig.3 Safety booth for handling with nano material (Push-Pull type)

Fig.4 Safety booth with glove ports

Fig.5 Replacement of HEPA filter, Bag-in-Bag-out method

Fig.6 Standard safety booth

Fig.7 Installed safety booth at customer's site

Applications

- R&D work or handling of hazardous substances

- Sampling, measuring, repacking to smaller sizes for raw material or products

- Filling/discharge of fiber drum, big bag IBC

- Prevention of dust scattering during powder processing such as grinding, sieving, and mixing or overhauling.

- Handling process of Nano particles

Feel free to contact us. if you have any questions or concerns.