- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Annual Publication "Micromeritics"

- Industrial Property Rights

- Journals and Books

- Technical Information

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Flexomix FX, FXD

Flexomix FX, FXD

Summary

Continuous mixer and agglomerator; a rotating shaft with angled blades in flexible chamber where a set of pneumatically operated rollers moves up/down to deform the chamber. Homogeneous mixing and humidification without blockage can agglomerate adhesive material. Although the unit shows compact exterior, it can be operated at high capacity. Product size is in the range of 0.1 to 2mm with porous structure and with narrow particle size distribution.

The more wetting proceeds, the larger agglomerates are produced. However high moisture content changes the agglomerates to highly adhesive nature, which makes continuous operation impossible. Providing self-cleaning mechanism, the Flexomix can handle such adhesive material. The external roller movement flexes the mixing chamber to prevent the wall from build-up of product. This unique self-cleaning mechanism realizes the production of highly moist agglomerates in mass production.

Principle

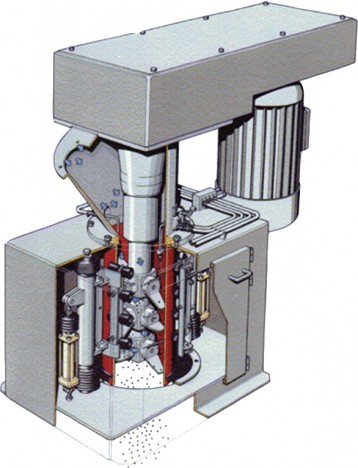

A rotating shaft with blades locales in the center of a rubber made flexible chamber. Feed inlet and two liquid injectors are provided at the top of the equipment.

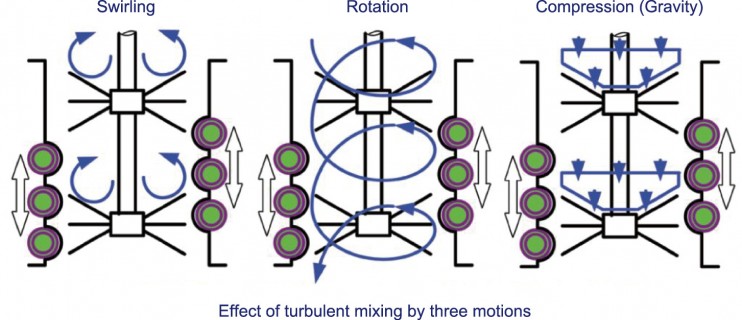

Blades are installed in three different angles and create strong turbulence to the powder at the max speed to 3000rpm. Powder is continuously fed from the top. Turbulence gives the combined force to the powder swirl, rotation and compression. In this turbulent mixing stage, liquid is injected for mixing and uniform wetting. In case of higher humidification, powder is wetted for large agglomerates and it is repeatedly wrapped up by sprayed liquid drop and grows to porous and large agglomerates.

Rotating speed of rotor and angle of blade is to adjust the strength of turbulence, residence time and dispersing force. Together with these parameters, liquid adding ratio, choice of binder, or feed rate enables to produce agglomerates in various properties.

A self-cleaning mechanism consists of a flexible chamber and the surrounded rollers. This external rollers move up and down to flex the mixing chamber to prevent the inside wall from build-up of product. Practically in the agglomeration process, adhering and peeling of the material is repeated.

Fig.1 Schematic structure

Fig.2 Self-cleaning mechanism

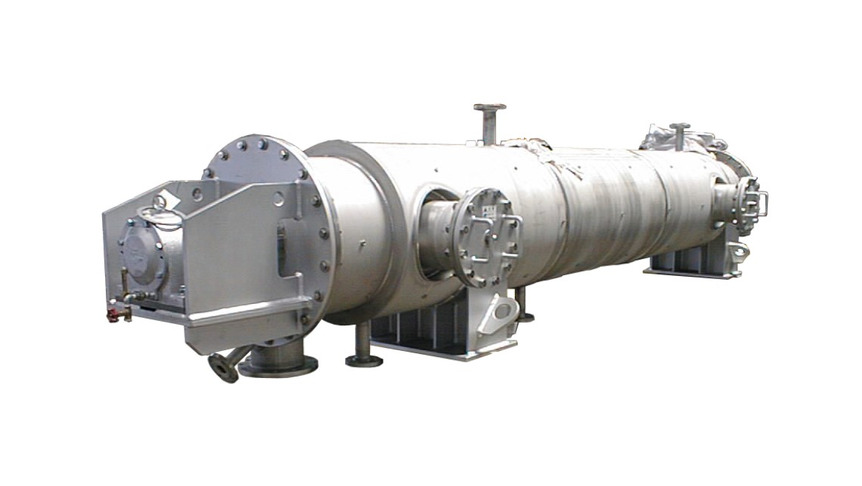

Fig.3 Flexomix FXD-250

Fig.4 Principle

Features

Fig.5 FXD-100 in pharma design

Highly soluble agglomerates (instant product)

Porous and highly soluble agglomerates of 0.1 to 2mm particle size. (raspberry structure)

Continuous process

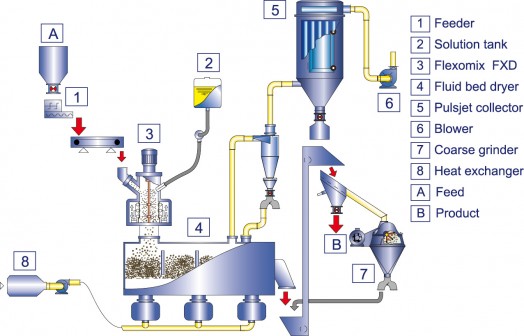

A continuous process consisting of weighing feeder, metering at pump and post drying process realized operator friendly and low energy operation at mass production.

Short residence time.

Mixing, wetting and agglomeration complete in 0.2 to 1 second.

Compact machine with large capacity

By continuous process and short residence time, a series of models covers the capacity of 50kg/h to 25t/h.

Saving energy process

Unique agglomeration mechanism realizes the low energy operation of 2 to 4kWh/t.

Highly applicable for high liquid adding ratio

Flexible chamber with self-cleaning mechanism is applicable for high liquid adding ratio and adhesive material.

Extremely high mixing ability

Specially designed rotor gives 3 different movement; swirl, rotate and compression by gravity.

Multi components processing

Agglomeration of 4 liquids and 2 powders are simultaneously processed.

Self-cleaning mechanism

The external rollers moved by compressed air around the flexible mixing chamber prevent the inside wall from build-up of product.

Easy maintenance

The external rollers double open to left and right from maintenance. Flexible chamber and injectors are easily dismounted. Simple construction and short down time for disassembling and cleaning.

Fig.6 Flexomix FXD-400

Fig.7 Flow

Applications

Chemical

Super absorbent polymers (SAP), detergents (drying, compounding before cooling, agglomeration), LIB anode phosphate (hydro exothermic reaction), pigment, or pesticide.

Mineral/metal

Nickel/cobalt (compound or agglomeration for LIB cathode), graphite (for secondary battery), tungsten carbide (for molding material), carbon black (for press material).

Food

instant food (dairy product, cocoa, soup for vending machine), animal feed, bakery additives, spice, flour (wetting), starch (reforming), milk substitute.

Pharmaceutical

Animal antibiotics, lactose.

Related equipments

Feel free to contact us. if you have any questions or concerns.