- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Annual Publication "Micromeritics"

- Industrial Property Rights

- Journals and Books

- Technical Information

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Vitomix VX

Vitomix VX

Summary

The Vitomix is a batch mixer with a conical vessel and two ribbon screws mounted on an orbit arm. Based on the proven mixing principles of the Vrieco Nauta Mixer, the Vitomix achieves faster mixing speeds. From gentle mixing like the Vrieco Nauta Mixer to higher speed mid shear mixing, the screw speeds can be adjusted for meet the product requirements. With a vessel designed for optimum mixing, the Vitomix has a shorter height compared to a Vrieco Nauta Mixer with comparable volume. Discharge of the material with almost no residue is possible with the conical vessel and the bottom discharge ball segment valve. A big access door on the vessel side for easy cleaning and inspection of the interior is provided. The Vitomix can be suited for the mixing of powders or powders and liquids. It is also suitable as a replacement for a Vrieco Nauta Mixer to increase capacity and for mixing where higher shear is required. it is also suited for mixing of large variety, small lot products.

Principle

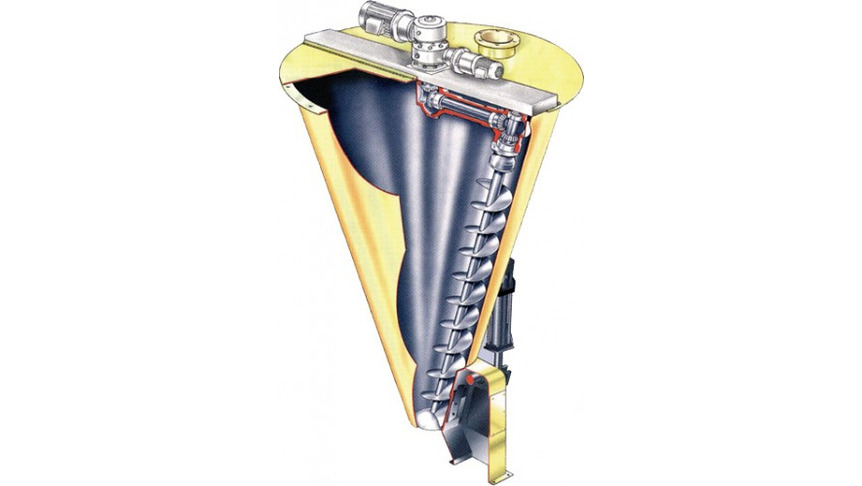

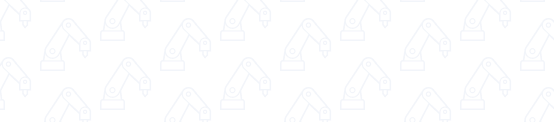

Fig.1 Schematic structure

The Vitomix has a conical vessel with the drive system at the top. The drive rotates an orbit arm around the centerline of the vessel and the two ribbon screws at both ends of the arm. The ribbon screws increase in diameter from bottom to top. The angle of the conical vessel is bigger from the vertical compared to the Vrieco Nauta Mixer reducing the machine height.

The rotating screws lift the product upwards and the material farther from the screw flows down due to gravity. The rotating orbit arm and ribbon screws efficiently move the entire product promoting swift mixing. The tip speed of the ribbon screws are adjustable between 0.8 to 5 m/s and can be used for low speed, gentle mixing to high speed, mid shear mixing. At high speed the material bed is fluidized and fluidized mixing occurs.

Features

Short mixing times

Achieves swift and homogenous mixing with an efficient mixing principle

Wide range of applications

Combines a gentle low shear mixer and a mid shear mixer in one machine

Easy discharge of material, no residue

The conical shape and the bottom discharge, makes material discharge simply and with no residue.

Easy to clean

The interior is a simple design with 2 ribbon screws. The big access door on the side of the vessel allows for full access to the interior for cleaning. Material changes are made simpler.

Compact design

Height of the mixer is lower than a comparable volume Vrieco Nauta Mixer

No seals in product

With the drive system at the top of the machine, no shaft seals are inside the product. Damage to the shaft seals due to wear from material friction is minimized.

Fig.2 Ribbon screw

Fig.3 Vitomix VX-800

Fig.4 Big door

Applications

Other information

Fig.5 Sample taker

Fig.6 Lump breaker

Applications

Foodstuffs + oil, graphite + alumina, granulated sugar + aspartame + spice, polymer + additive, inorganic powders, sodium acetate + coating with glycerol esters of fatty acids, coloring

Related equipments

Feel free to contact us. if you have any questions or concerns.