- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Annual Publication "Micromeritics"

- Industrial Property Rights

- Journals and Books

- Technical Information

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Fine Impact Mill UPZ

Fine Impact Mill UPZ

Summary

The UPZ is a high-speed impact type fine grinding machine that can be equipped with 4 different types of hammers and 3 types of liners/screens. By equipping the machine with variations of the hammers and liners/screens, the machine can process various types of raw materials and achieve a wide range of particle sizes. The UPZ is ideal for the producing the following products:

•Fine products with sharp top-size limitations.

•Products with high flowability without overgrinding.

•Production of powders with high bulk densities.

•Production of powders with similar particle sizes within a specified size range.

Principle

Rotor

The raw material enters the machine from the middle of the grinding chamber and is then dispersed by the centrifugal force generated by the rotor. Once dispersed, the powder is ground by the impact from the hammers.

The principle can be seen by follwoing movie.

The following are the 4 different types of rotors that the UPZ can be equipped with.

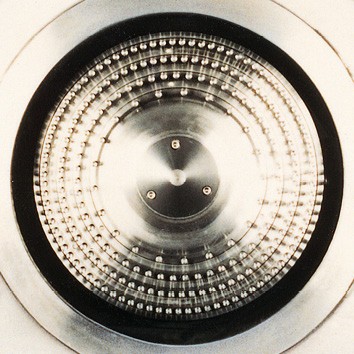

Pin Disc unit (Fig.1)

Fig.1 Pin Disc unit

- A combination of pin mills with one rotating and one stable.

- Suitable for raw materials with a hardness of up to 3 on the Mohs scale, and that have less than 0.1% of adhesive materials within them.

- Suitable for fine grinding.

- Low energy consumption

- Minimal generation of heat during the grinding process.

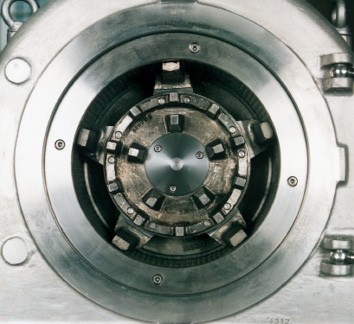

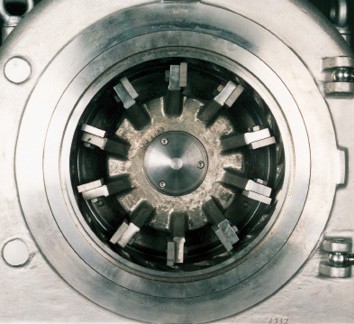

Beater Disc unit (Fig.2)

Fig.2 Beater Disc unit

- Beaters made of wear-proof cast steel.

- Combination of a rotating grinding rotor on the housing side, and stationary grinding rotor on the door side.

- Suitable for grinding agglomerates in a single process.

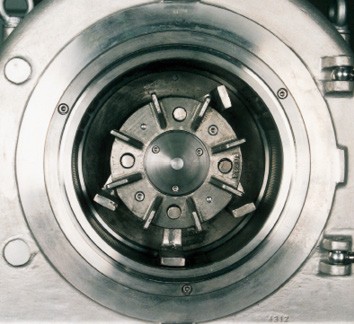

Swing Beater unit (Fig.3)

Fig.3 Swing Beater unit

- Heavy-duty beaters made of wear-proof case metal.

- Wear-proof treatment available.

- Suitable for coarse feed materials.

- Can produce powders with medium fineness values.

Plate Beater unit (Fig.4)

Fig.4 Plate Beater unit

- Equipped with wear-resistant beater plates that generate powerful impact.

- Achieves extremely fine powders comparable to the pin mill.

- Generates high airflow for grinding of heat-sensitive and adhesive materials.

Liner and Screen

All hammers except for the pin disc unit can be equipped with the following liners/screens.

All Around Screen (Fig.5)

Fig.5 All Around Screen

- The whole perimeter is constructed with a screen. 2 different screen shapes are available. (RN and RT type)

Long Liner (Fig.6)

Fig.6 Long Liner

- A liner is equipped on the door side of the grinding chamber. The products are discharged through the gap on the shaft side of the machine.

- There are 2 types of liner shapes with 10°or 30° angles (door-side to shaft side). Depending on the installment direction (forward or backward) and choice of liner, the product size and capacity can be adjusted.

Screen equipped short liner (Fig.7)

Fig.7 Screen equipped short liner

- A combination of the previous screen and liner.

- Bottom discharge (standard) or tangent direction discharge types available constructed in carbon steel or stainless steel (SS304, 316, 316L) welded housings.

- Anti-explosion construction (meets ATEX94/9/EC requirements) maximum explosion pressure 10 bars (G) / PSR 11.

- Specifications for pharmaceutical use available: surface treatment, mono-block, CIP/SIP, installment in an isolator, etc.

- Specialized connection flange, bearing unit, air filtration, etc.

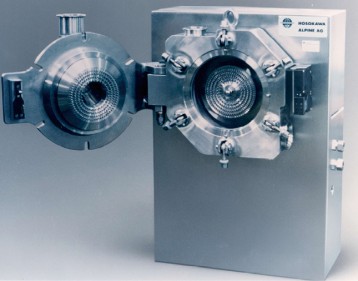

Features

Fig.8 Fine Impact Mill 100UPZ-C (Pharma model)

- Has many variations available for the grinding structure and can be used for a wide range of applications.

- Simple grinding structure for easy assembly and disassembly.

- CIP/SIP compliant model available

- The 100UPZ-c manufactured specifically for pharmaceutical applications can be easily disassembled for cleaning and is GMP compliant.

Fig.9 Fine Impact Mill 160UPZ (Pharama model)

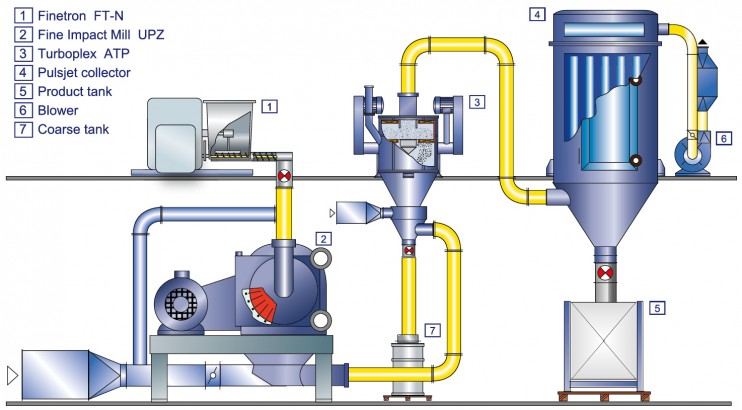

The UPZ is an impact type grinding machine that has a vast number of optional parts for use in many different applications. The machine can be operated on its own, with a bag filter, or with a classifier to classify the coarse and fine material.

Fig.10 Flow

Related equipments

Feel free to contact us. if you have any questions or concerns.