- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Turbo Twin Air Classifier TTC[NEW!]

Turbo Twin Air Classifier TTC[NEW!]

Summary

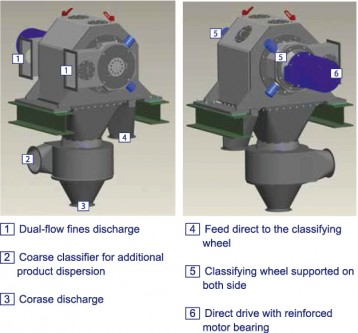

The ultrafine Turbo Twin Air Classifier TTC is the first new development from the leading suppliers of ultrafine classifying systems. Developed in 2011, this classifier is second to none when it comes to classifying soft to medium-hard minerals at high throughputs, for example in the production of fillers. The patented classifying wheel geometry of the Turbo Twin permits high throughput rates and loading factors at high fineness values of up to d97 = 2.0μm. Due to the low pressure drop of the TTC, this machine is characterized by its high energy efficiency. Savings of up to 25% are possible.

Principle

The classifying wheel is supported in bearings on both sides and permits extremely high peripheral speeds of up to 120 m/s. Another unique feature is the optimized product routing direct to the classifying wheel. This prevents any backmixing with the already classified coarse material. It is no longer necessary to adjust the classifying wheel gap, which simplifies maintenance tremendously. There are currently four machine sizes available: 315, 500, 800, and 1,000.

Features

- Low energy costs per ton of end product

- Low investment costs per ton of end product

- High fines yield and maximum fines capacity

- Extremely robust and durable construction

- Classifying wheel supported in bearings on both sides

- Dual-flow fines discharge

- Optimized product feed direct to classifying wheel

- Direct drive with reinforced motor bearing

- Cost-optimized operation

- Compact and functional design

Applications

- Soft to medium-hard products

- Industrial fillers

- Limestone, marble, GCC

- Talc

- Dolomite

Fig.1 Schematic figure of TTC

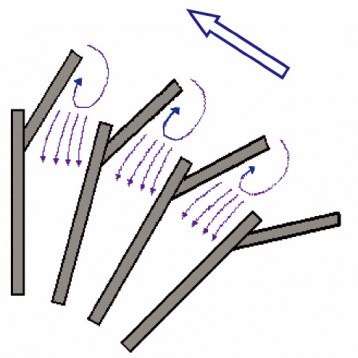

Fig.2 Stream line in classifying wheel

Other information

TTS Model

The second and most recent development is the Turbo Twin Single TTS. This classifier belongs to a newly designed series of single-wheel classifiers. The development is based on the established ATP/NG technology and is impressive thanks to its compact design. The TTS is designed for medium-sized fines yields in the mineral powder and filler industry. Just as with the TTC, the TTS is characterized by its low pressure drop and thus reduced energy consumption. Over and above this, its ease of maintenance is convincing.

Feel free to contact us. if you have any questions or concerns.