- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- PENETO ANALYZER PNT-N

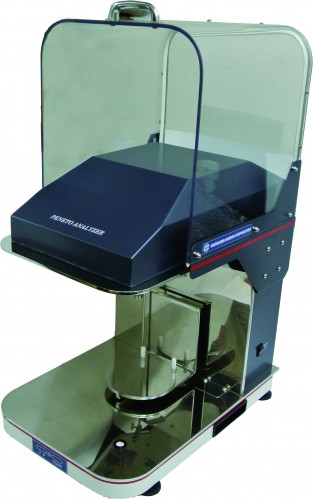

PENETO ANALYZER PNT-N

Summary

The Peneto Analyzer PNT-N is the instrument to evaluate the affinity between powder and liquid, i.e. ,wettability by measuring the speed and mass of the liquid penetrating into the powder bed. In the actual powder process, the dry powder is utilized in wet phase such as coating or molding for the final products. It is important to evaluate the wettability of the powder for the new material or quality control. PNT-N is possible to evaluate wettability of powders as well as sheet or block such as porous material, fiber, or paper. A series of the Peneto Analyzer “PNT”s have been delivered to various industries since 1986. Hosokawa has totally changed the model Peneto Analyzer to “PNT-N” to meet the various requirements from the industries.

The new developed cell (Colanta cell) can evaluate adsorb ratio, wettability, and absorb amount of OD(Oral disintegrant) tablet or film coating tablet.

("PENETO ANALYZER" is a registered trademark of HOSOKAWA MICRON CORPORATION in Japan)

Principle

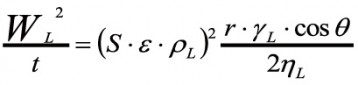

Common measuring method of wettability of powder with liquid is to measure the contact angle by the micro scope. However, the preparation of the powder sample such as tableting and polishing method does not represent the powder property and the surface roughness greatly affect the result. On the other hand the Peneto Analyzer measures the penetration mass of liquid into the powder bed by capillarity action. The penetration speed into the powder bed is fast, if it has high affinity. Washburn’s equation shows the relationship between the penetrated height and contact angle with the assumption that the powder bed forms the uniform capillaries. The result of the term of penetrated height can be replaced to the penetrated mass as Equation 1. The Peneto Analyzer can indicate the contact angle by the following equation for measuring the mass of liquid penetration.

Washburn’s equation;

Eq.1

Where, WL: mass of liquid penetration, t: time, S: cross section area of the cell, ε: void ratio, ρL: Liquid density, γ: Radius of capillary formed in powder bed, γL: surface tension of liquid, ηL: Viscosity of liquid, θ: contact angle between liquid and solid surface.

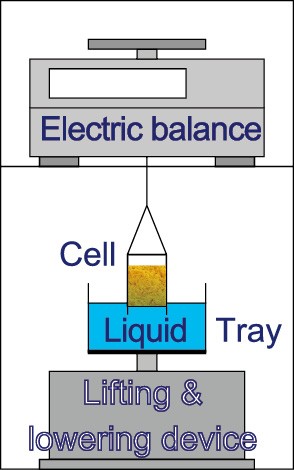

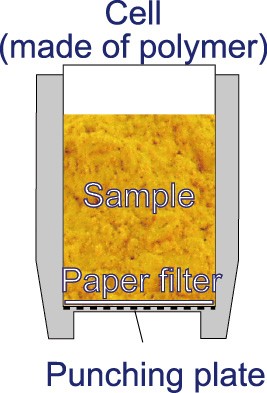

The unit is consisted of weighing balance, measuring cell, liquid vessel, and lifting device. Measuring cell is hanged to electrically connected the electric balance. The vessel is set to contact powder bed and liquid. The Peneto Analyzer start lifting the cell and record the mass in real time.

Fig.1 Schematic figure

Fig.2 Cross section of cell

Features

Fig.3 Powder

No special pretreatment

Pretreatment is only tapping the powder bed. Simple measurement to hand the cell on the balance. No need to conduct any molding or firing which is different from the common contact angle measuring method. PNT-N can measure the material in the forms of powder sheet or block.

Accurate and reproducible measurement

- Controlled lifting device accurately decides the lifting level and it realizes the highly accurate lifting motion conduce accurate measurement.

- Tapping condition affects to pore distribution in the powder bed and the measurement reproducibility. We provide the dedicated tapping unit. This unit controls the tapping stroke and number of tapping with high-accuracy. The stable tapped condition improves the reproducibility of measurement.

Easy operation

- Operation is easy by the control software made by Windows®7. The control software can display by different windows during the measurement.

- (Windows is a registered trademark of Microsoft Corporation in the United States and other countries.)

- The acrylic cover of unit opens up and down, it is easy to access to the working area.

Applicable sample and liquid (solvent)

- Sample : Powder, Porus block, Fibers, Sheet-like material and powder coated foils,

- Liquid (Solvent) : Water or organic solvent with high flowability like as linseed oil.

Applications

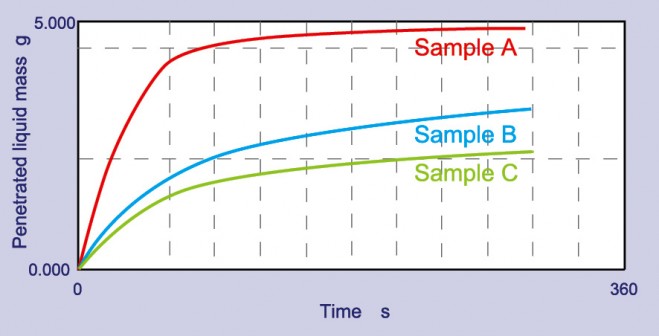

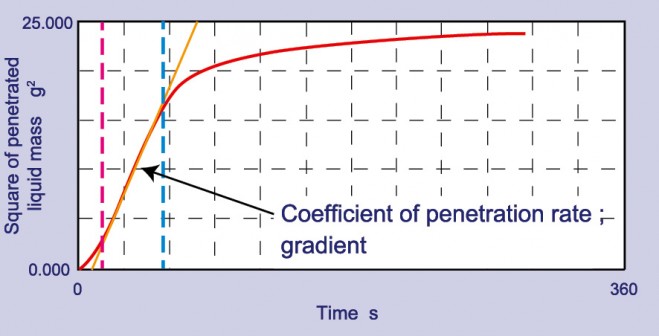

Fig.4 shows the measurement examples for 3 samples (Sample A,B and C) to water. PNT-N indicates the difference the penetration speed (affinity to water) between these samples. The gradient of the linear section of the curve in Fig.5 equals to the coefficient of penetration speed in the left term of Washburn’s equation.

Fig.4 Reference-Penetrated weight

Fig.5 Reference-Obtaining the coefficient of penetration rate

Optional apparatuses for measuerment of battery material

Peneto Analyzer can measure the wettability of electrode of battery, especially Lithium Ion Battery (LIB), by applying the optional apparatuses.

(Figs.6~8)

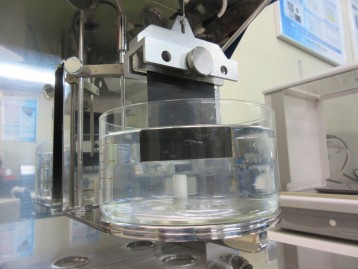

Fig.6 Apparatus for electrode foil (for example, powder coated aluminum or coppper foil)

Fig.7 Cylindrical cell for insert the rolled foil

Fig.8 Measuring situation by applying the cylindrical cell for rolled electorode

It is suitable to evaluate various formulation parameters like as tabletting pressure, various properties (chemical formulations, particle size, morphology, etc.) of diluent or disintegrant for OD / pre-coating tablet.

Fig. 9 Colanta cell for measuring the pharmaceutical tablet

Reference of measuring of absorption of colored water into OD tablet Colanta cell (special designed for tablet measurement)

Feel free to contact us. if you have any questions or concerns.