- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Filling and Weighing System STS

Filling and Weighing System STS

Summary

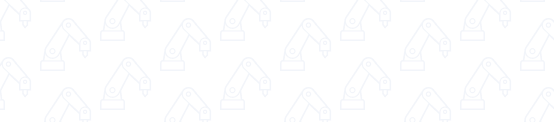

The Stott Filling and Weighing System is a unique filling system utilizing a combination of inflatable packing head and a pinch valve feeding system that enables the accurate filling of powders into various kinds of bags or containers in an easy to operate, dust free environment.

There are various types of packing heads optimized for use on wide mouth bags (plastic bags, paper bags, aluminum lined bags), fiber drums or flexible containers. The Stott Filling and Weighing System is used for filling of various powders in the chemicals, pharmaceutical and food industries where powders are used. It is especially suited to improve work conditions in filling operations where dust generation is high, product losses due to removal of dust is high, filling accuracy is bad. For materials that require it, filling in nitrogen or dry air is also possible.

Principle

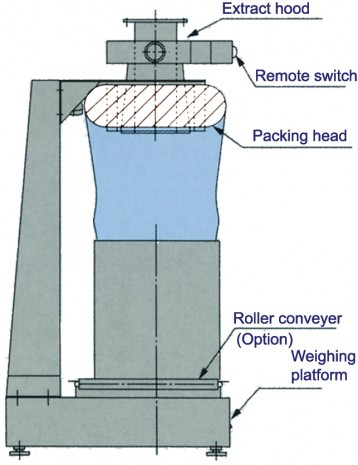

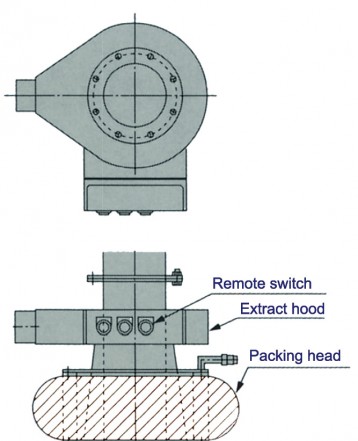

Fig.1 Schematic structure

Superior dust prevention with expanding packing head

A dust removal feature is integrated into the expandable packing head. After setting the bag, the expandable packing head is inflated with compressed air sealing the bag prior to filling. The inner diameter of the packing head is constructed to create an optimum flow of air for dust removal. This design also minimizes the flow of material out of the bag and to the dust collector. The effect of the dedusting air on material weighing is minimal. The amount of inflation of the packing head is adjustable with a pressure regulator allowing the use of bags such as paper bags that are easy to tear.

Pinch valve feeding system

At the end of the weighing sequence, a pinch valve is used for fine adjustment of the weighed material. Just prior to reaching the set weight (for example at 90% of the set weight), the pinch valve closes stopping feeding into the bag. The feeder continues to feed material on top of the closed valve as the material for fine adjustment then stops. The pinch valve slightly opens and a vibrator activates starting the final fine feeding. When the weigh reaches the set weight, the pinch valve closes, completing the weighing sequence. This control function contributes to a very accurate filling. The opening of the pinch valve is adjustable with proximity switches on the pneumatic cylinder.

De-dusting airflow adjusting system

After filling is completed, the packing head is deflated. At the same time an integrated valve opens increasing the de-dusting airflow. This removes any free-floating particles and deflates the bag increasing handle-ability.

Features

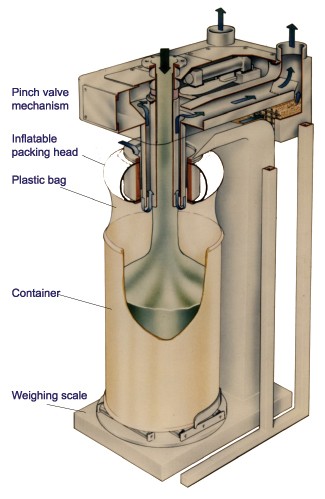

Fig.2 Flow

- Can be used to fill and weigh various bags and containers

- No dust generation allowing a clean working environment

- Work is conducted safely and easily with high work efficiency

- Guaranteed high weighing accuracy

- Compact construction

- Can be incorporated in to various systems

- Many options available

Applications

Used for filling of various powders in the chemicals, pharmaceutical and food industries.

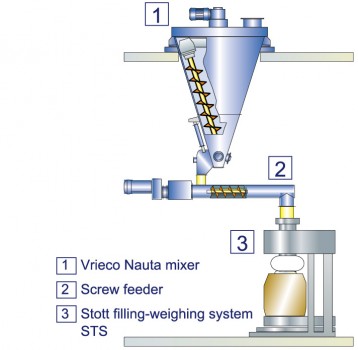

Below is a description of the filling process.

Fig.3 Filling-Weighing process

Specifications

Stott Standard System (Model: STS)

Filling and weighing system with integrated pinch valve feeding system.

Fig.4 Big bag system BBS

Big Bag System (Model: BBS)

Filling and weighing system for flexible containers. Optional pinch valve feeding system can be installed.

Packing Head System (Model: PHS)

Filling and weighing system for wide mouth bags, fiber drums

Packing Head Unit (Model: PHU)

For use where weighing is not required. Since the system is operated with just pneumatic equipment without the use of electrical components, can be used where explosion proof equipment is required.

Fig.5 Packing head system PHS

Fig.6 Packing head unit PHU

Easy Clean Model

Fig.7 STS Easy disassembly type

The powder contact parts are easily disassembled for cleaning. Used in pharmaceutical and food applications.

Other information

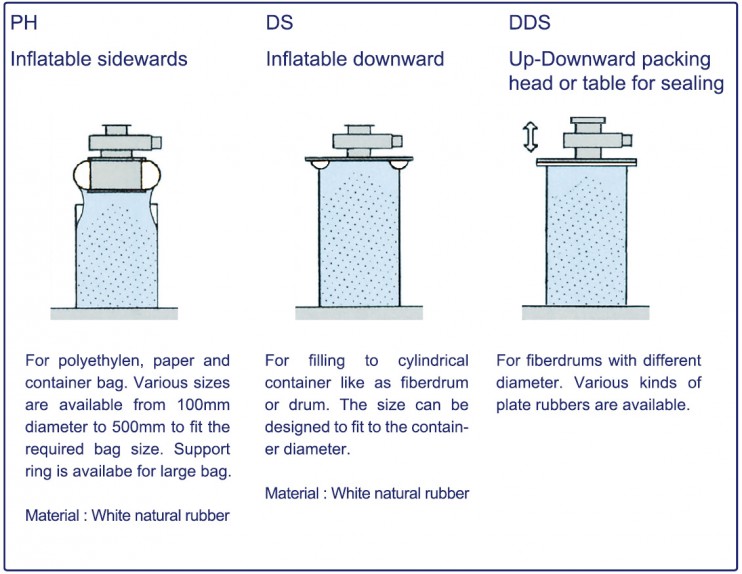

Fig.8 Packing head options

Packing Head Options

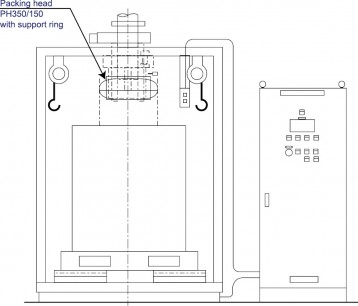

Fig.9 Packing head and support ring

For plastic liner bags for flexible containers with a opening of 600mm diameter or bigger, a packing head support ring is used. The plastic bag is held in place between the packing head and the support ring. The bag may be wrinkled where it is held in place by the packing head, but no powder leaks.

Feel free to contact us. if you have any questions or concerns.