- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Denspack DEN

Denspack DEN

Summary

The Denspack is a deaerator type of densifier designed to be used for the high density filling of bags and flexible containers. Powders can be deaerated without damage just by passing through the compact rotary airlock type body. Using the Denspack as a feeder for the filling of flexible containers or bags can help reduce shipping costs and increase operability of filling operations.

(Denspack is a registered trademark of HOSOKAWA MICRON CORPORATION in Japan)

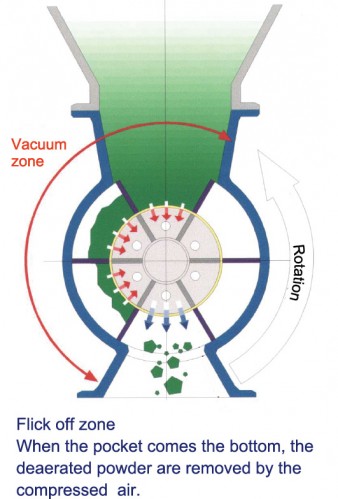

Principle

Fig.1 Principle

Fig.1 shows a cross section of the Denspack. The powder enters a pocket in the rotor which has a metal filter at the bottom. The air is pulled out of the pocket through a metal filter by a positive displacement blower as the rotor turns. When the pocket reached the bottom, the deaerated powder is pushed out and the metal filter cleaned. The cleaning step keeps the metal filter performance optimal for continued densification performance.

Features

- Compact construction, big densification effect

- Densification with no damage to the powder

- Continuous operation possible with the integrated self cleaning mechanism

- Can be easily integrated into production systems

- Can operate even with sticky powders

- Can be used as a feeder or discharger simultaneously with densification.

- Running cost is low due to low energy consumption

- Easy to operate and maintain

Applications

Used as a discharger from tank or volumetric feeder at the powder processing system, because of its compact shape.

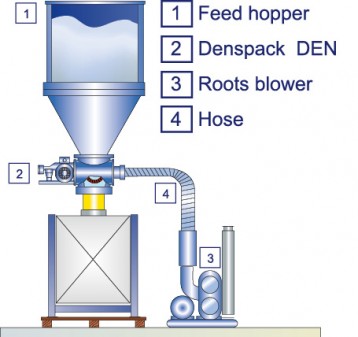

Fig.2 Flow 1

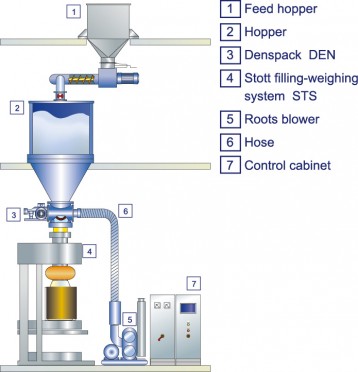

Fig.3 Flow 2

Feel free to contact us. if you have any questions or concerns.