- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Solidaire SJ

Solidaire SJ

Summary

The Solidaire is the indirect heating dryer of a mechanical agitator rotating in a cylindrical housing. Heating from Jacket and high dispersion by high speed agitator proceed the heat transfer from heating media to the material. It is suitable for drying the material in the constant rate period or drying adhesive material. Small amount of gas volume is suitable to collect volatile solvent. Indirect drying gives less damage to heat sensitive material such as food or resin.

It is applicable to wide application such as resin, chemical, mineral, food, pharmaceutical, pigment, or dye. It is also used as a temperature rising machine for solid phase polymerization of polyester/polyamide.

Compare to the other indirect dryer such as rotary dryer, Solidaire gives high heat transfer efficiency because of the agitating mechanism, compact, smaller installation space and saving energy.

Principle

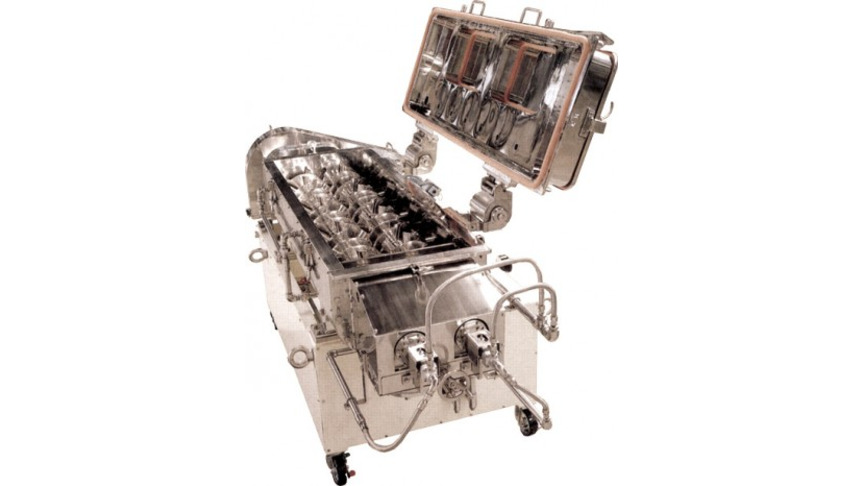

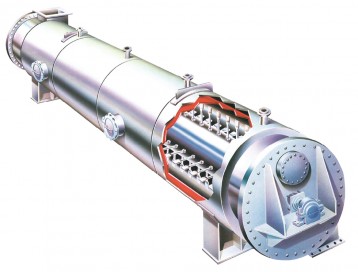

Fig.1 Schematic structure

The cylindrical housing provides with a heating (cooling) Jacket, the agitator equipped with a number of paddles. Heating media for Jacket are applicable with hot water, steam, or thermal oil. For cooling purpose, industrial water, cooling water, or cooling media are applicable. Drying temperature can be controlled by adjusting media temperature. Paddles can be adjusted at three different angles (45°, 135° and 180°) to transport the material forward or backward and to control the residence time of the material in dryer. The tip speed of the paddle can be set at 5 to 15m/s, witch controls the dispersion force and drying time.

Thus, adjusting operating parameters; jacket temperature, paddle angle, and/or rotating speed of rotor, the optional drying (cooling) condition can be found for the specific material.

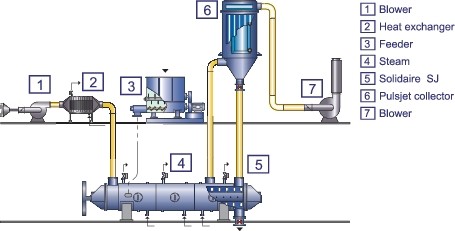

The carrier gas flow is applied to prevent condensation inside the dryer and to take out fine powders. Direction of gas flow can be set at opposite to material flow or the parallel to material flow. In case of drying flammable material or dust explosive material, the inert gas (such as N2) is applied as a carrier gas to ensure the safe operation under the explosion limit oxide concentration.

Features

- High dispersion effect enables to dry high moisture content material and caked material to product moisture content to several %.

- Paddles break the agglomerates contained in the material and avoids secondary agglomeration generated while drying to produce powdery products.

- Drying time can be controlled by adjusting angles of paddles and/or rotating speed of rotor.

- With inert gas operation such as N2 as a carrier, it is possible to dry easy oxidized material or to recover volatile solvent.

- It is possible to conduct crystallization of PET resin in short process time,although the fluid bed dryer or vertical agitating dryer causes adhesive problem. Solidaire can give a stable and highly crystallized product.

- As required carrier gas is minimized, ancillary equipments such as blower, heater, or bag filter can be designed compact.

- Because of high heat transfer coefficient, small space requirement and low running cost are realized.

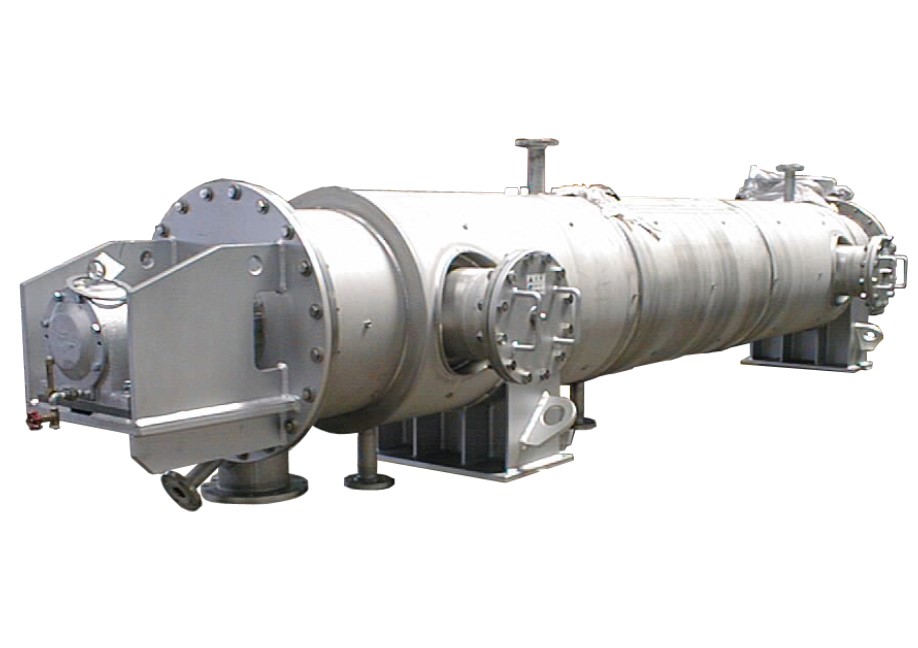

Fig.2 Flow

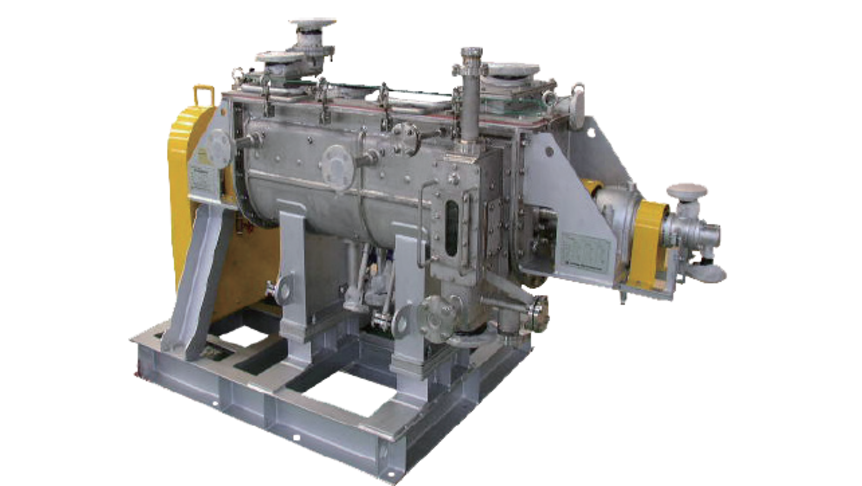

Fig.3 Solidaire SJS-48-24

Related equipments

Feel free to contact us. if you have any questions or concerns.