- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

Sugar

Summary

Various foods use a powder sugar which is ground granule sugar. The amount of coarse particle decides the grade of powder sugar. Generally speaking, 93.5% < 200Mesh (75 micron) are suitable size for confectionery usage. Sometime more fine powder called silk sugar is demanded. Both sugars can give a creamy frosting or icing on cakes or some pastries. But these fine powders cause problems in the manufacturing process and in use. Due to the high specific surface area, the fine powder tends to cake easily generates, absorbs moisture, and easily dust. To prevent these problems, a coarser powder sugar around 100-150micron is still generally used. The powder sugar has following advantages.

- Good for large scale process automatic conveying

- Free-flowing

- Very fine but dust free

Contents

Fig. General sized powder sugar

Hosokawa Micron Group propose mass production processes for manufacturing fine, coarse (general size), and ultra fine powder sugars, respectively

General powder sugar

It is widely applied to the consumer market. The range of particle size is in 100-150 micron as mean particle size. A lot of types of mill are commercialized, however, unfortunately most of those equipment are hard to satisfy following requests.

- Continuous operation

- Stable quality of ground product, for example, constant particle size distribution.

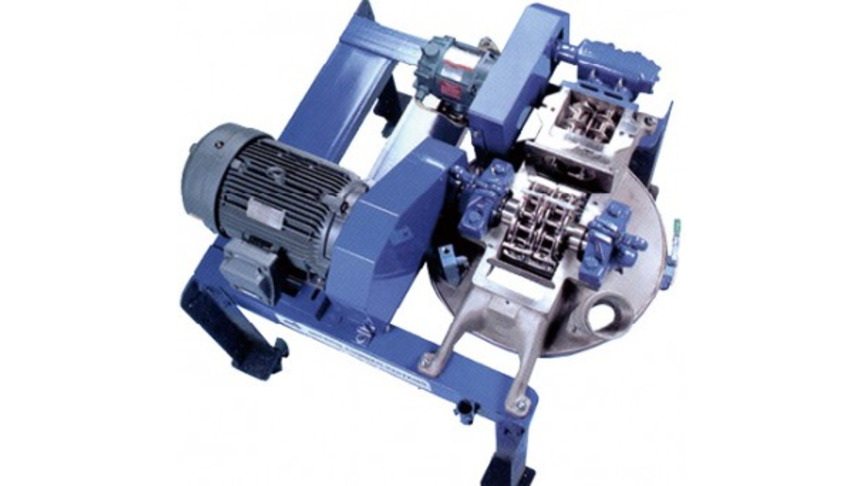

The HOSOKAWA/MIKRO Pulverizer, type AP can satisfy both requests. The good cost performance, robust & stable operation, and the unique structure for easy disassemble - assemble are the reason why over 10,000 units of the Pulverizer has been delivered for food grinding in the world. The particle size can be adjusted by changing the built-in screen. There are a lot of installations for this application in the Asian countries.

The following is an example of typical performance of AP.

Capacity : 300 kg/h, Product d50 : 60 µm

Fig.1 HOSOKAWA/MIKRO Pulverizer, type AP

Fine powder sugar

Fig. 4 Fine powder sugar

from 2X (82%<200Mesh [75micron]) to 12X (98% < 325Mesh [45micron])

Pin mills are widely used for the range, for example, The HOSOKAWA/ALPINE Sugar plex and the HOSOKAWA/ALPINE Contraplex fit to the purpose.

Fig. 5 Sugarplex

Fig. 6 Contraplex

Ultra fine powder sugar

Fig. 7 Icing

Silk sugar (97% < 20.5micron)

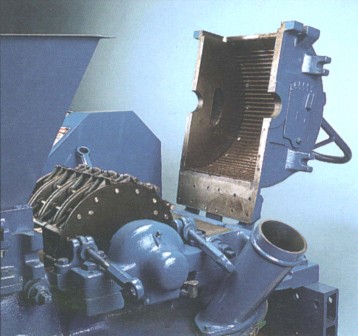

The HOSOKAWA/MIKRO ACM Pulverizer fit to the range due to the high performance of grinding and precision classification by integrated classifier.

All manufacturing system should consider the prevention of explosion and dedusting. Hosokawa Micron Group can offer suitable design for depending on your plant scale and demand.

Fig. 8 ACM Pulverizer

Related equipments

Feel free to contact us. if you have any questions or concerns.