- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Instant Food

Instant Food

Summary

Due to the increasing market for convenient food products, the instant characteristics of food and beverages are gaining importance. This ‘instantizing’ technology applies for many products like instant cocoa, dry soups and the wide variety of products provided by vending machine. In most cases, original powders are not sufficient instant product. The powders may float or become jelly lumps in water/milk. The properties of the powdery products have to be optimized to achieve a better wettability and solubility.

Contents

Agglomeration

Agglomeration is the solution to improve instant characteristics. By forming the porous agglomerates, the characteristics are optimized.

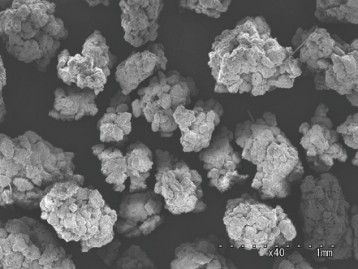

In order to produce a constant and reproducible product at high rate, continuous process would be preferable. The Flexomix continuous agglomeration process would be the most appropriate for the production of the porous agglomerates of the size between 200 and 1500 μm with raspberry structure.

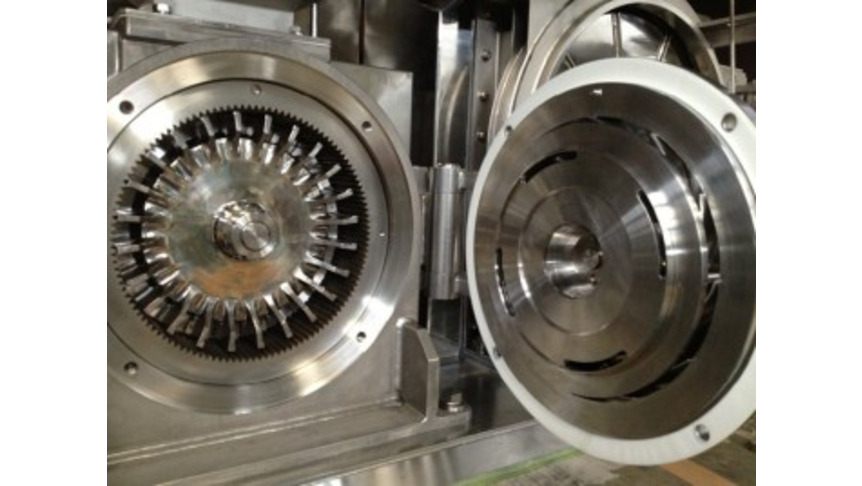

Fig.1 Raspberry structure

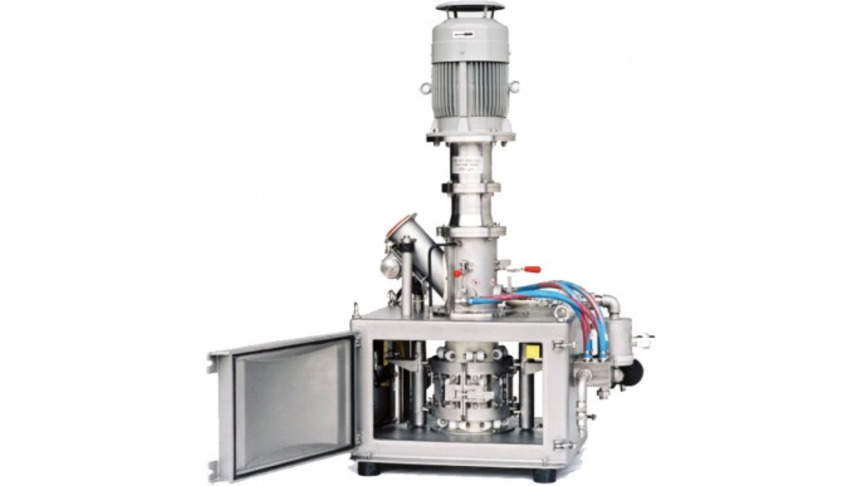

Fig.2 Flexomix FXD-100

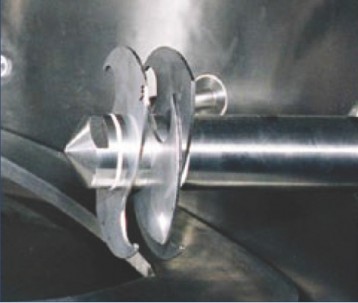

Fig.3 Self cleaning mechanism

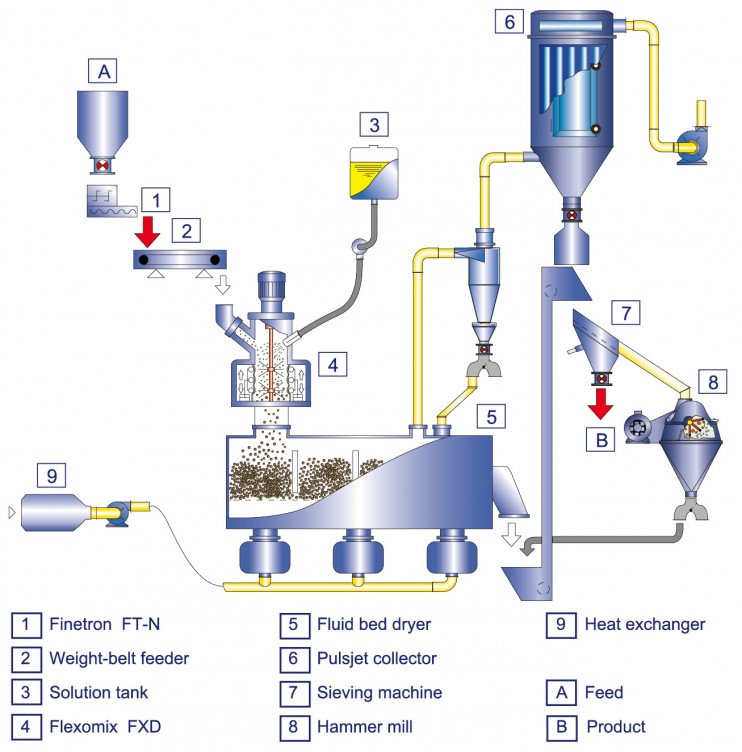

Typical flow of Flexomix system is shown in Fig.4.

Continuous agglomeration system by Flexomix requires the equipment shown in the flow diagram Fig.4. However, the actual process has to be designed on each application.

As the product made by Flexomix system is the porous agglomerate (raspberry structure), it shows high solubility. It is very applicable to the instant cocoa, instant soup, coffee, noodle soup, and daily product including the product for vending machine.

Fig.4 Flow

Mixing

Fig5. Instant soup

Various instant soups are available in every supermarket. Their quality is evaluated by the homogeneity and solubility in hot water. An additional requirement is gentle mixing of additives (dry vegetables and croutons) without damage.

Fig.6 Ribbon screw

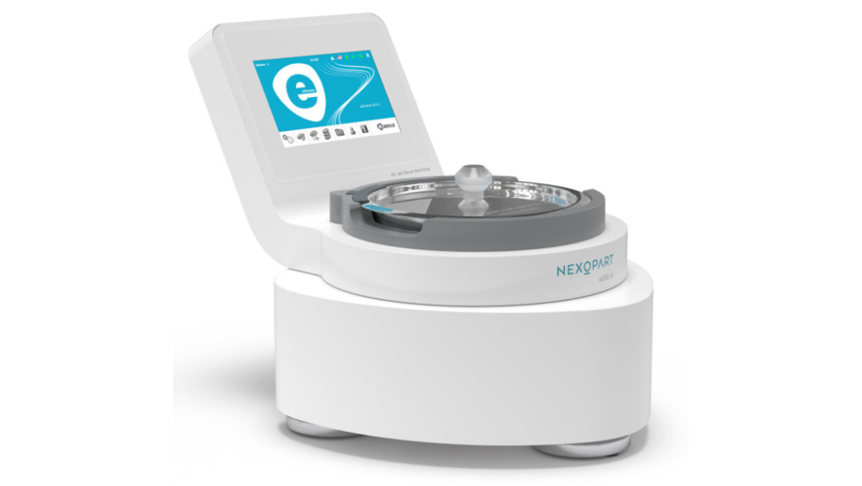

Fig.7 Vitomix VX-800

Fig.8 Sample taker

Production line

Fig.9 Lump breaker

The production capacity of instant soup is always batch-wise operation, because of wide variety in recipes. This requires easy and fast cleaning intervals and to preventing the equipment from cross-contamination of taste and smell.

The mixing process has to guarantee low energy consumption per kg product. In order to cover these tasks, visually acceptable quality and no damage of components in the mixture.

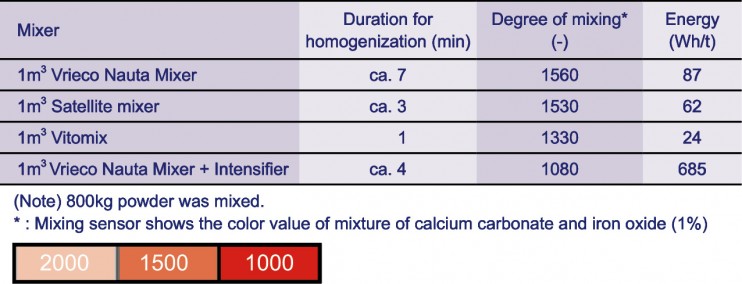

The system normally consists of two separate mixing processes. One is the intensive bulk mixing process (starch, salt, fat) and the other is the gentle post mixing process of the specific soup components (vegetables, tomato-powder, mushrooms, vermicelli, etc). The first intensive mixing process is executed in paddle mixer or plough shear mixer, the second gentle mixing process is typically carried out by Vrieco Nauta mixer.

Features of Vitomix

Fig.10 Big door

Modern technology covers both mixing processes; namely, Vitomix, thereby reducing cleaning time, intermediate storage, material handling, and improving product quality. The intensive mixing phase is conducted at high speed, but the post-mixing step is conducted at low speed to avoid the damage of the product. The mixer is equipped with a big door for cleaning and an Isem Ball segment valve for complete discharge.

Table 1 Comparison of mixing performance

Related equipments

Feel free to contact us. if you have any questions or concerns.