- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Fertilizers

Fertilizers

Summary

Due to worldwide increase of population in areas such as South East Asia, India and Africa, the demand of chemical fertilizer required in the cultivation of agricultural products is also increasing. To increase the productivity per crop acreage, chemical fertilizer with suitable ingredients blended per each type of crop or BB (Bulk Blending) Fertilizer, for which ingredients can be adjusted by blending of raw materials, are widely used and increasing in worldwide demand as well. In general, granular product is preferred in the market because it can avoid dust generation during distribution and give the advantage in durability.

Contents

In the BB Fertilizer, granular raw materials; nitrogen, phosphate salt and potassium are blended on purpose. To avoid segregation during mixing each granular sizes should be adjusted and 2-4mm sizes are suitable which are easy to handle and dusting is minimized. Premixed chemical fertilizer, which includes required ingredients are also adjusted to 2-4mm sizes. These granular fertilizers are easy to distribute with minimum dusting and do not stick to each other during storage, therefore demand is rising. Conventionally, rotating drums, i.e. tumbling granulation process, produces granular fertilizers. Because the granulation process requires liquid binder, drying is mandatory. Thus, high production cost is unavoidable in the wet granulation. As we have developed dry granulating process without liquid binder, granular products with lower production cost and superior product quality are now available.

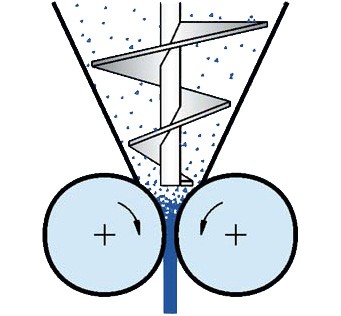

In the dry granulating process, dry compaction process replaced the conventional tumbling granulation. It forms plate - like molds from powder material by strong compression force. The plate is ground by hammer mill to granular form and sieved to target size range. By roller drum (Fig.2), granular edges are rounded as well as treated with anti-blocking agent. Compared with the conventional product granular durability is improved and distribution property is increased because of round shape granular and less dusting.

Fig.1 Compactor image

Fig.2 Drum for surface coating

Fig.3 Compactor

Fig.4 Product example

Related equipments

Feel free to contact us. if you have any questions or concerns.