- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Sustainability

- TOP

- Sustainability

- Contributions towards a safer, more secure and prosperous society

- Issues related to products

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

Issues related to products

Product Safety Initiatives Safety Considerations/Chemical Hazard Prevention

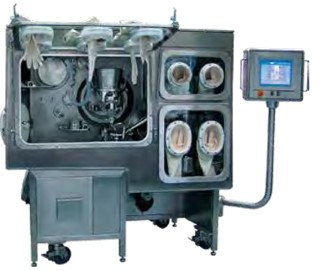

In recent years, in addition to highly active pharmaceuticals handled in the pharmaceutical field, there has been an increase in the manufacture of high value-added products using raw materials that are difficult to handle under normal atmospheric conditions in the rechargeable battery field and other processes involving volatile materials. With our accumulated know-how and containment technology, we are incorporating a variety of safeguards for handling and processing hazardous chemical materials.

Product Quality and Safety Initiatives (Cosmetics)

User-friendly product creation (eyelash serum)

We are developing products with more safety in mind for the delicate eye area.

Conducting four safety studies

- Patch Test (Skin Allergy Test)

- RIPT test (skin allergy test)

- Stinging test (sensitivity test for sensitive skin to evaluate itching and burning sensation)

- Alternative eye irritation test

Five free formulations

Free of silicone, ethanol, oil, fragrance, and colorants

Acquired ISO22716 (Gojo Plant, cosmetics GMP: Good Manufacturing Practice)

- Gojo Plant (Gojo City, Nara Prefecture)

Acquired on June 15, 2022

* ISO 22716 is an international quality and safety standard for the manufacture of cosmetics.

It is a "Good Manufacturing Practice" regarding the manufacturing and quality control standards required of manufacturers, and is recognized as a set of management standards for a series of processes in the manufacture of cosmetics, from raw material procurement, manufacturing, packaging, shipping management, and handling of recalls.