- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

IIoT

System control of powder processing

Example of a controlled milling system

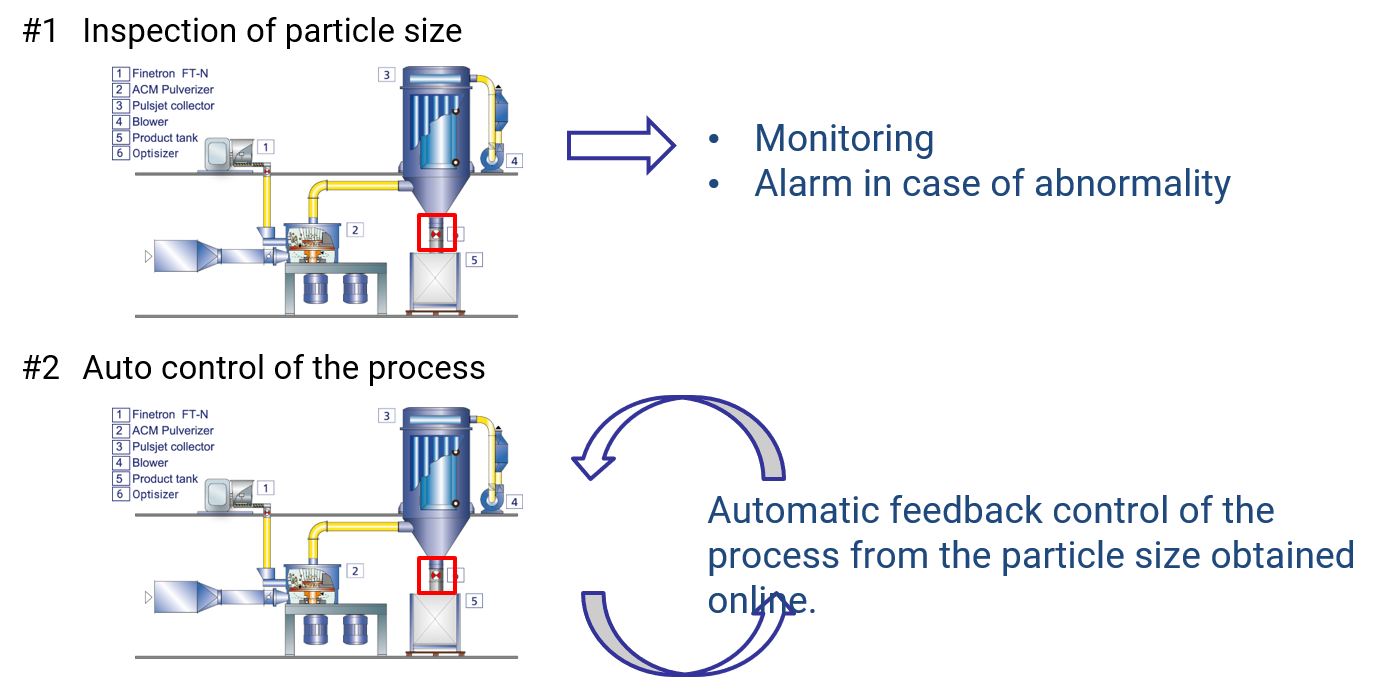

Remote monitoring of the ACM Pulperizer with GEN4 RM and examples of controlled production using on-line sensors and controllers will be presented.

A variety of information is required to monitor and control the operation of powder production systems. Among these, powder size is a very important parameter, but unlike liquids and gases, powders are difficult to sample. In order to achieve this goal, we sell the Optisizer, an online particle size analyzer.

.png)

Optisizer®/Online particle sizer

This is an online particle size analyzer that can measure the particle size distribution of powders flowing through a manufacturing process in real time and monitor it on a PC screen. Monitoring the particle size distribution of powders in a production line using this system reduces the time and cost required for quality control and process control, and contributes to improved productivity and product competitiveness. It can also be used as a measuring instrument for quality control when processing dusty and explosive materials in inert gas, because it can measure the particle size distribution without sampling in the air.

This optimizer allows for remote monitoring of production status and automatic control of the process.

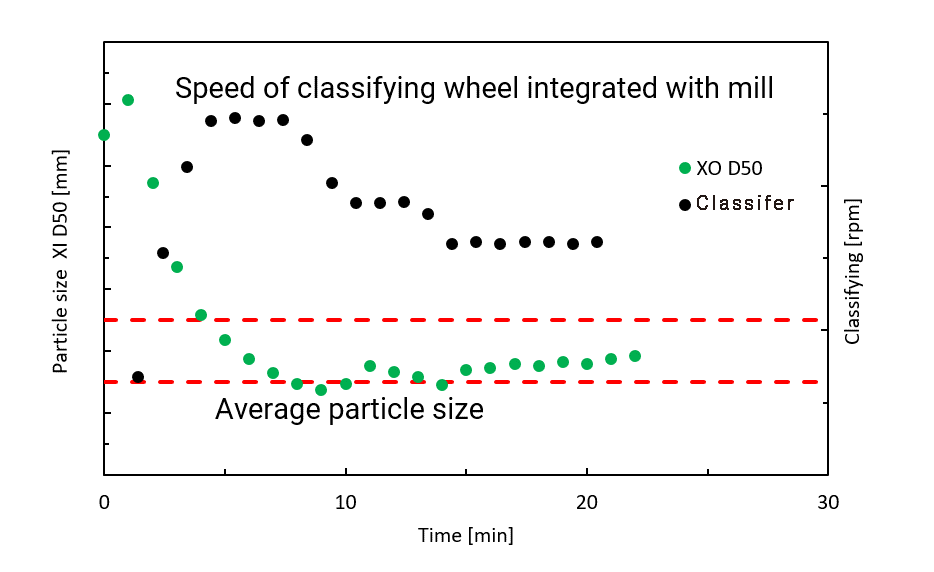

The figure shows the result of controlling the ACM classification speed based on the particle size data produced by the ACM Pulperizer and the Optisizer. The classifying rotation speed is controlled by the control panel. The classifying rotation speed is programmed to be automatically adjusted by the controller built into the control panel. If the fine adjustment of the operating conditions has been done by the operator, this control can contribute to the stabilization of the production quality and to the problem of technical inheritance of the operation.