- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- VIBLETTE VBL-F[NEW!]

VIBLETTE VBL-F[NEW!]

Summary

Innovation of conventional measurement method!

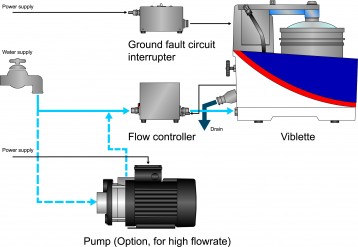

Water or other liquid is sprayed to powder or slurry on the sieve for wet sieving.

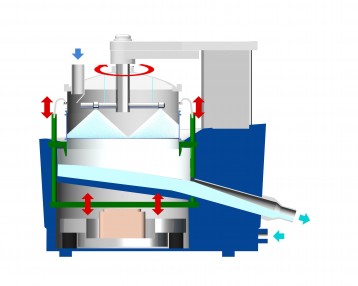

Principle

Fig. 1 Principle

Water is sprayed through the rotating sprinkler nozzle to disperse the sample. The Viblette is supplied with a vibration mechanism to assist in the dispersing of the sample agglomerates and the breaking of potential liquid membranes on the sieve in order to achieve stable sieving.

Features

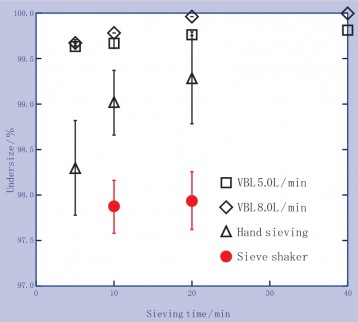

Fig. 2 Example of Sieving Performance

Current Wet Sieving

- Excessive time needed

- Messy process

- Splashing Liquid

- Inaccurate measurement values

- Process skill required

to

Advantages of the Viblette

- Reliable measurement values

- Reduced analysis time

- Repeatable measurement protocol

Achieve accurate measurement results within a short time.

For Nonoparticle - Barium titanate -

Fig. 3 Ultra sonic type, VBL-FU

Ultrasonic type

For wet sieving of strong cohesive powders, Ultrasonic + mechanical vibration model (VBL-FU) is suitable instrument.

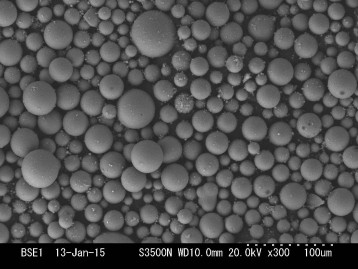

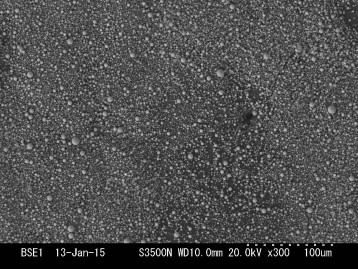

Sieving silica particles with the Viblette

Below sieving silica particles are using a 5μm screen with the Viblette VBL-F-Ultra.

Fig. 4 SEM, particles on the sieve with 5 micron opening

Fig. 5 SEM, passed particles from the sieve with 5 micron opening

Fig. 6 VBL-FS

VBL-FS, Explosion proof & Solvent correspondence model

(Sorry, we don't have data in the brochure)

Applications

- Magnesium hydroxide:Flame retardant

- Hydrated lime:Soil improvement

- Titanium oxide:Ink, Cosmetics

- Carbon black:Ink, Tire

- Pigment:Inorganic pigment, Organic pigment

- Silica:Sealant for electronic device

- Barium titanate:Laminated ceramics capacitor

- Superhard particles:Abrasive grain

- Manganese dioxide:Battery material

- Disintegrant:Tablet auxiliary

Other information

Fig. 6 Layout

Feel free to contact us. if you have any questions or concerns.