- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Micron Jet-T MJT

Micron Jet-T MJT

Summary

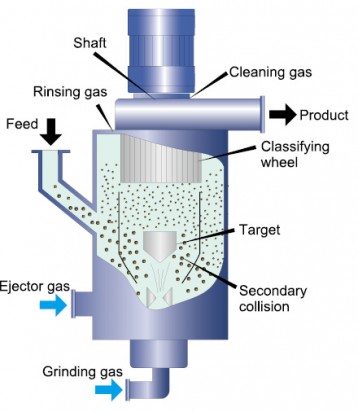

The Micron Jet is a highly energy efficient jet mill constructed with a unique impact grinding mechanism. Fluidized bed-type jet mills require a certain amount of materials to be left within the grinding chamber for efficient grinding. This type of grinding mechanism is undesirable for materials with values. The Micron Jet utilizes an impact method, which allows materials to be ground efficiently. Its structure also allows materials to circulate between the grinding and classifying chambers, which eliminates the need for leftover materials. In recent years, this process has been used in grinding systems that reduce oxidization of materials from inert gases, as well as for production of high functional materials such as magnetic materials.

Principle

Fig.1 Structure

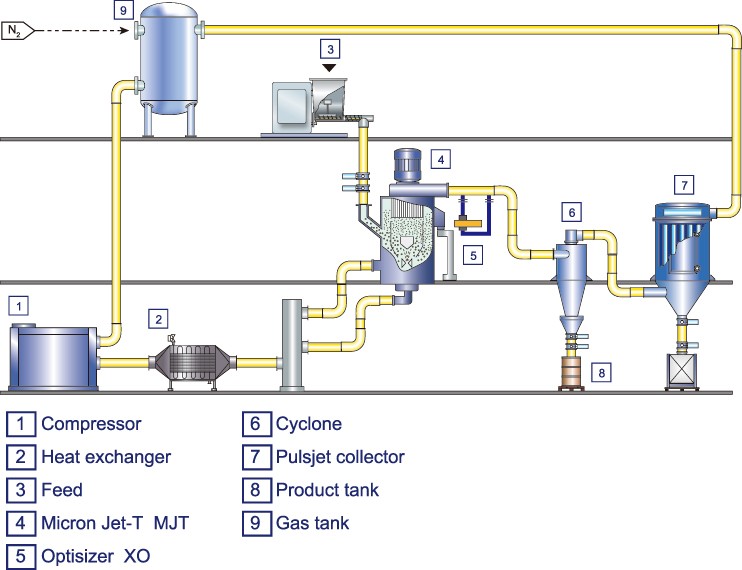

The Micron Jet is a target jet mill with a rotating classifying rotor for precise product size control. The raw material is accelerated by the high pressure jet stream generated from the nozzle located at the bottom of the machine and hits the impact plate, from which the impact causes the particles to be ground. Particles that pass through the impact chamber are then carried to the classifying rotor at the top of the unit and are classified to the required particle size. Fine particles that have been classified by the rotor flow to the product collector, and any coarse particles drop to the bottom portion of the unit where the side ejector effect carries them back to the grinding chamber. Product sizes can be easily adjusted by changing the rotation speed of the classifying rotor. The Micron Jet T type inert gas circulation system consists of a feeder, the Micron Jet T type mill, cyclone, bag filter, and a compressor.

Features

High grinding efficiency

The grinding efficiency has been drastically improved by its unique impact structure.

Easy adjustment of product size

The classification point can be easily adjusted by changing the rotation speed of the classifying rotor.

High classification effectiveness

The ground materials are carried to the classifying chamber in a dispersed state, which allows for an effective classification.

Raw materials can be easily changed in a compact area

The number of items that make up the Micron Jet system are very limited which allows for easy cleaning even in a compact area.

Easy Cleaning

The unit structure that has considered the cleaning process can be easily disassembled. The hydraulic system that can be attached to the classifying section allows opening and closing procedures to be stress free.

Applications

- Utilization of nitrogen gases (N2) as well as inert gases for grinding of rare-earth materials. (neodymium iron boron, samarium cobalt, etc.)

- Grinding of toner

Color toner

Fig.2 Flow of closed loop grinding system

Related equipments

Feel free to contact us. if you have any questions or concerns.