- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Disintegrator RD, RH, RA/RP, RI

Disintegrator RD, RH, RA/RP, RI

Summary

The Disintegrator is a coarse grinding machine that can be widely applied to various industries such as the food industry for processing vegetables, fruits, fish meats, as well as chemicals, plastics (resins), pharmaceuticals, etc. It can perform dry milling or wet milling depending on the application. Depending on the Disintegrator type, the rotor is set onto a vertical, horizontal, or angled driving shaft. The installed screen surrounds the rotor by 360 degrees. Raw materials that are fed into the chamber are dispersed and ground by the rotor. Any material that passes through the screen is then discharged through the circumference of the machine. There are models that have structures where hard impure materials (such as nails, iron materials, etc.) can be discharged separately. All models are structured in a manner for easy assembly, disassembly, and cleaning. Models such as the RD, RH type dispersetron, RA, RP, RI types all have separate structures to best suit specific applications.

Principle

RA/RP type : Angled shaft type

The raw material is fed from the upper portion, while the product is discharged and collected from the bottom side. The rotor is set on a 45 degrees angle, with the inlet having an open structure due to the bottom drive structure. The upper case, screen is fixed by a clamp band, and the hammer has a simple structure, which allows for easy installation and removal. By removing these parts and opening up the grinding chamber, the machine can be easily washed. The belt driving type is called the RA type, and the direct motor drive type is called the RP type. The RA type can be structured to discharge impure materials.

The grinding chamber is angled at a 45-degree angle, which makes it a suitable machine for grinding and slurrying apples, vegetables such as tomatoes, and whole fruits for food applications. It has an easy cleaning structure allowing for simple raw material exchange.

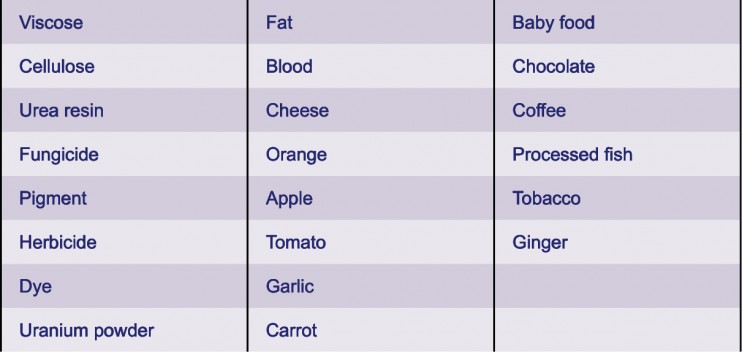

Fig.1 RP Type inside

Fig.2 RA Type inside

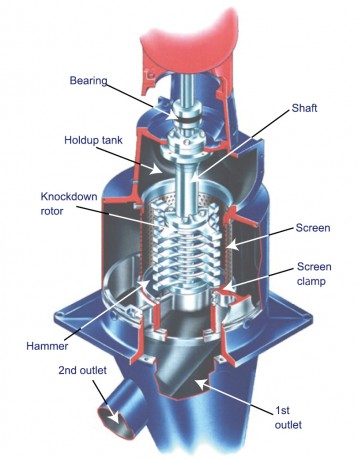

Table 1 Applications

RD type : Vertical shaft type

Fig.3 Sectional view of RD Type

The rotor is structured vertically, with the raw materials being fed from the upper portion via a feeder such as a screw feeder. The raw material is kept within the grinding chamber by the upper feed hammers and bottom lift hammers with slanted tips. The raw material is then dispersed and ground by the remaining middle hammers. For materials that can be ground easily, under certain circumstances the bottom rotor is removed. Materials that pass through the 360degree primary discharge screen are collected as products. Impure materials are separated from products and discharged from the machine through a separate outlet. When there are no impure materials within the raw material, the machine is operated with the plate for impure material discharge closed. In a standard flow, products are suctioned and collected by a bag filter. The 360-degree primary discharge screen ensures uniform product size and reduces the temperature rise of the product. This model is suitable for grinding hard-to-grind materials such as lumber, coal, and grains, which include many impure materials within them.

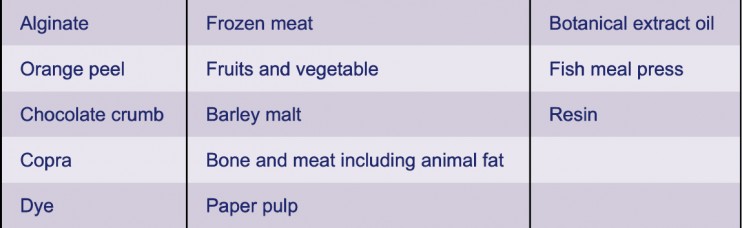

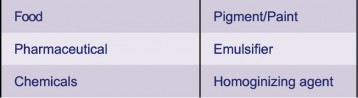

Table 2 Applications

RH Type : Dispersetron

Fig.4 RH Horizontal shaft type

The rotor is fixed in a horizontal position with a 360-degree screen surrounding the rotor. It can be directly attached to storage tanks and will disperse moist raw materials. Processed materials will then be pushed out to the product collection tank.For any raw material that requires an intense mixing process, it can utilize a circulation system for repeated dispersing.

RH Type-2 : Horizontal shaft type

This type also has a horizontally positioned rotor with a 180-degree screen fixed on the bottom portion of the rotor. The rotors are equipped with abrasion resistant hammers. By removing the access door, which also provides support for the shaft located on the opposite side of the drive side, the screen can easily be exchanged.This type is normally used under dry processes. The height of the main machine is relatively low, allowing for a compact installation.

Table 3 Applications

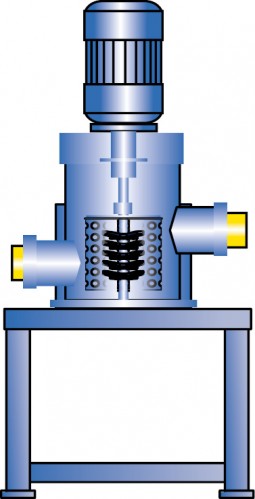

RI Type : In-line type

Fig.5 Sectional view of RI Type

The Grinding/Dispersing rotor is structured in the same manner as the RD type. It is equipped with fixed hammers and a screen that surrounds the rotor for 360 degrees. The raw material is fed into the upper portion of the machine by a pump and is then ground and dispersed efficiently by the rotor and screen. Any impure materials can be discharged from the bottom of the machine. Gland packing or mechanical seals can be selected for the shaft seal, allowing the machine to be installed in an in-line production process for paste, slurry, and other liquid materials.

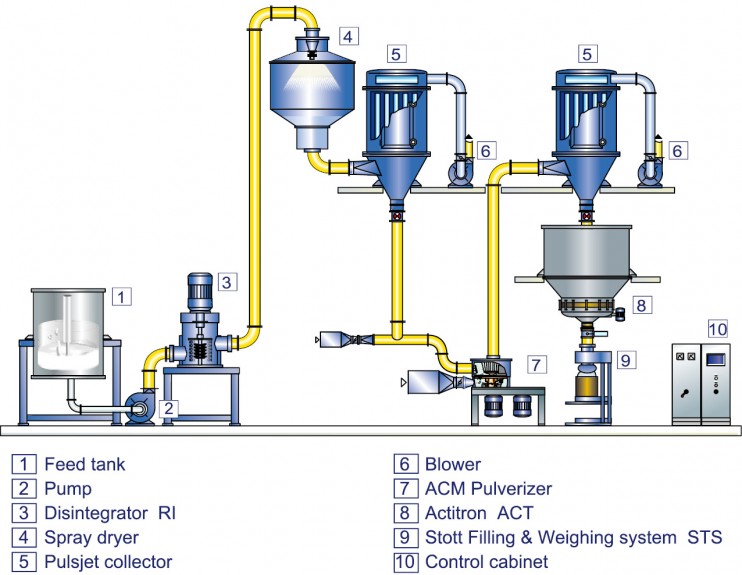

Fig.6 Flow of RI for pre-treatment of spray dryer (PVC paste resin)

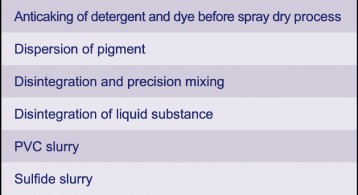

This type is usually directly installed in between the pipelines. It is most suitable for being installed before spray dryers for PVC paste and detergent production, to grind and disperse clumped materials which may lead to the nozzles of the dryer becoming plugged. Fig.6 displays a standard production flow. For detergent productions, we have past experiences of continuous operation for approximately 2 years without any nozzle blockage. The machine has a structure to remove impure materials from the bottom as well, which can minimize problems that may otherwise develop in the following processes. The machine is structured to discharge the impure materials periodically.

Table 4 Applications

Feel free to contact us. if you have any questions or concerns.