- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Contraplex CW

Contraplex CW

Summary

The Contraplex is a high-speed fine impact mill equipped with two opposing pin discs. A screen is not necessary and the large outer perimeter of the grinding chamber makes this grinder an ideal machine for grinding highly adhesive materials.

The counter-rotating structure found in the Contraplex can achieve much higher relative speeds in comparison to pin mills with only one rotating pin disc. The outer most pins on the pin disc can reach a maximum relative speed of 250m/s, allowing it to grind brittle raw materials with a maximum Mohs hardness of 3. The fineness of the product can be adjusted by altering the pin disc rotation speed. The centrifugal forces generated by the two pin discs and the wide grinding chamber design ensures that this grinder can process even moist, greasy, and adhesive materials. The grinder is also compatible with using liquid nitrogen to perform low temperature grinding.

(Contraplex is a registered trademark of HOSOKAWA MICRON CORPORATION in Japan)

Principle

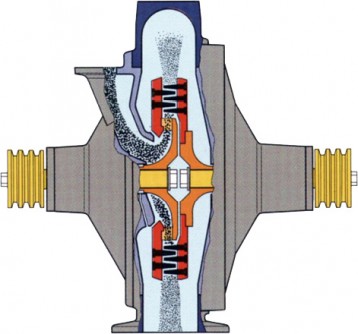

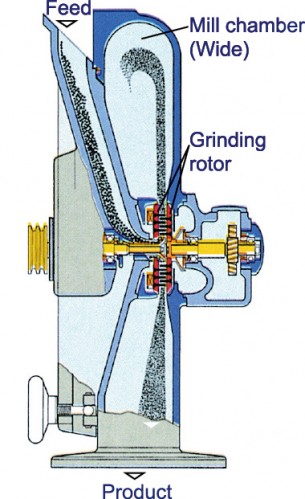

Fig.1 Structure of CW

The raw material fed to the middle of the grinding chamber is finely ground by the two rotating pin discs located on the main machine side and the door side of the machine. A dust-proof structure is adopted for the shaft portion to protect the bearing during long-run operations.

Fig.2 Structure of wide chamber type

Housing:

- Welded/casting housing structure

- Bottom discharge (standard) or tangential direction discharge is available

- Mild steel or stainless steel (SUS304, 316, 316L) construction

- Model 250-630CW

Pin Disc and Pins:

- Constructed from special steel

Bearing Unit:

- Bearing unit protected from dust penetration by rinsing air (automatic air intake or forced rinsing)

- Has a permanently lubricating or relubrication structure for cooling the bearing unit

Option:

- Safety interlock mechanism

- Pharmaceutical specification available

- Explosion-proof design corresponding to ATEX 94/9/EC. Designed to withstand a maximum explosion pressure of 10 bar (G)

- Wear protected pins

Features

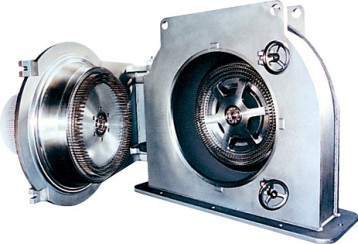

Fig.3 Contraplex 800CW

- The wide grinding chamber structure allows generated heat to be discharged efficiently and prevents adhesion buildup.

- The high relative speeds generated by the two pin discs allows for fine grinding.

- The strong impact generated by the pin discs allows for an equal grinding mixture for raw materials made up by more than one substance.

- It is ideal for raw materials with Mohs hardness 3 and lower as well as materials with contaminations less than 0.1%. (silica, zirconia ceramics, etc.)

- The screen-less structure is ideal for processing materials with high wear and adhesive characteristics.

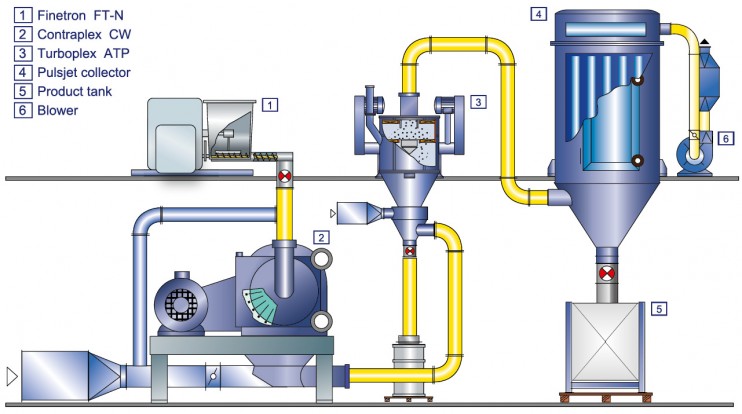

Fig.4 Flow

Feel free to contact us. if you have any questions or concerns.