- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Rotoplex Ro

Rotoplex Ro

Summary

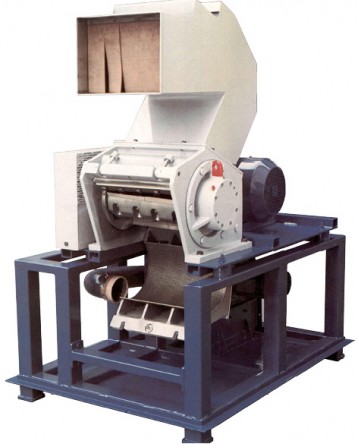

The Rotoplex is a cutting mill that utilizes the shearing mechanism. The raw material is severed and made to powder by the stationary and rotating blades. The product size is adjusted by the screen size. The Rotoplex is widely used for disintegration of large masses, pipes, boards, fibers, film, resin, rubber, sponge, and urethane foam, as well as grinding of foodstuffs, fish skin, pulp, fibers, and copper wires. It is equipped with a cross scissor cut rotor made of cast iron. This allows for a strong and durable structure, suitable for long operations. The Rotoplex is ideal for recycling applications of large inferior goods and disposable wastes.

(Rotoplex is a registered trademark of HOSOKAWA MICRON CORPORATION in Japan)

Principle

Fig.1 Rotoplex 90/300 Ro

From its horizontal shaft structure, the Rotoplex has the ability to grind many types of materials such as large resin molded inferior goods, bumpers for automobiles, plastic masses, films, and empty bottles.

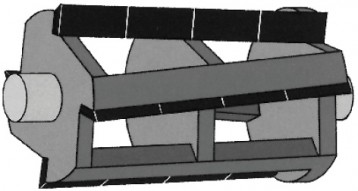

Cross Scissor Cut Open Rotor

The rotating cutters are installed on an inclined angle compared to the stationary cutters, which allow for a stable load condition. The open rotor structure prevents build-ups of the raw material and overheating.

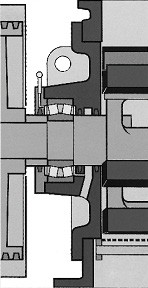

Original Shaft Seal Design

This design keeps the bearing from overheating as well as prevents raw materials from entering the bearing chamber and grease entering the housing.

Features

- Durable casing structure made from cast iron.

- Designed for easy cleaning and easy exchange of screens/cutters.

- Able to grind resin molded inferior goods of various shapes and sizes.

- Able to grind newly molded high temperature scraps.

- Cooling air and water are not needed due to its unique structure that is compatible to the high-speed rotor.

Fig.2 Cross Scissor Cut Rotor

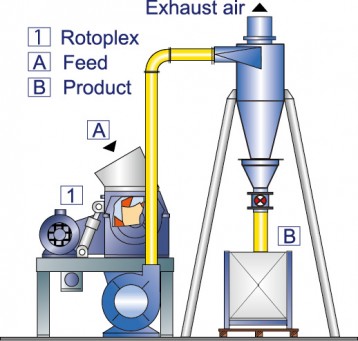

Fig.3 Flow

Fig.4 Shaft Seal Design

Feel free to contact us. if you have any questions or concerns.