- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

Flour

Summary

Flour is the milled wheat grain as edible. The wheat flour has been the most largely produced grain in the world. They are categorized as below.

-Clean (transparent)

-White (white color)

-Brown (brown)

-Hard (hard, high protein content, mainly for bread flour)

-Soft (soft, low protein content, mainly for cake flour)

Soft type is separated to cake flour, which has lower gluten or confectionery flour, which has a little more gluten. Cake flour is white flour made of fine milled soft wheat. It contains lower protein (8 to 10%) and is suitable for fine texture cake or cookies.

Contents

Wet heat treatment system for cake flour

Fig.1 Cookie

American cake flour is bleached. In the countries where bleaching is not allowed, heat treatment is applied instead of bleaching. Heat treated flour is produced for the purpose of filling functional property expected for the fragrant food (natural sauce, soup, or gravy.) Material is essentially required to have functional properties, such as heat-resisting, acid resist, or shearing stability for producing the heat treated food or dry mixing cooked food.

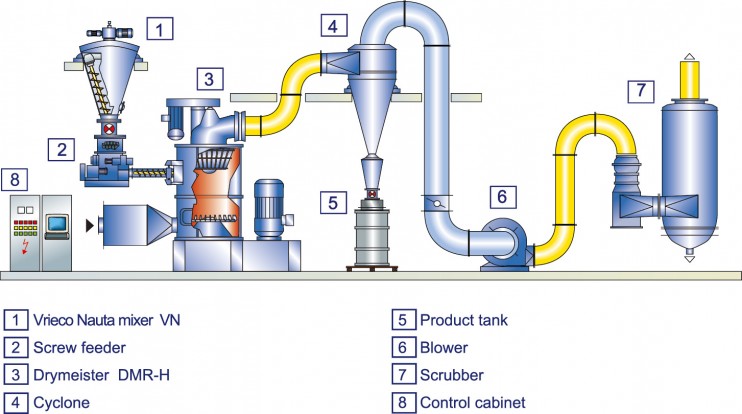

For the production of heat-treated flour, following points are important in cooking and drying process. This process consists of Vrieco Nauta mixer and Drymeister.

- Precise wetting amount

- Short residence time at drying process

- Direct and indirect heat input

Wet/heat process

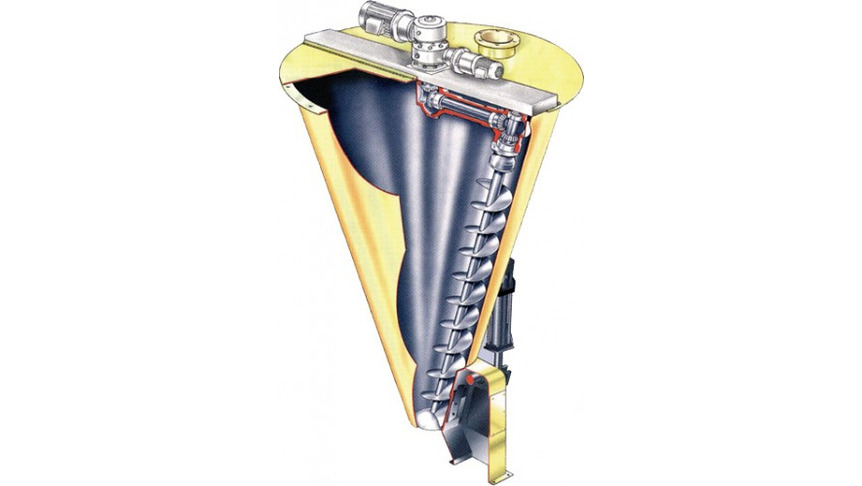

Fig.2 Drymeister DMR-1

For the flour of moisture contents of 4%, Vrieco Nauta mixer equipped with jacket should be applied for wetting and cooking. Blowing inside the mixer while mixing and cooking (aging) proceeds for 20 to 40 minutes. In this process, moisture of flour increases from 4% to 15%. When wetting and cooking cycle is finished, the product is discharged from mixer to hopper then, the product is immediately milled and dried by Drymeister. Moisture content of dried product becomes as the same as the feed, 4%.

Fig.3 Flow

Related equipments

Feel free to contact us. if you have any questions or concerns.