- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Pesticides

Pesticides

Summary

Hosokawa supplies complete systems for the manufacture of insect spray, dust or granules. Hosokawa/Alpine fine impact mill UPZ is used for this task. The particle sizes demanded for insect sprays range are achieved with Hosokawa/Alpine fluidized bed opposed jet mill AFG. These mills set new trends in the production of pesticides.

Contents

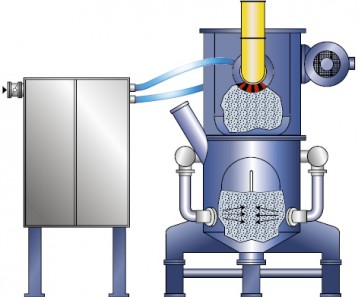

System schematic

Formulation system for the universal production of dust and sprays with different end fineness values and concentrations of active substances.

System classified as per ATEX 94/9 EC:

- Pressure-shock-proof section inside: zone 20

- Mixer inside: zone NEX, N2-blanketing

- Mixer outside: zone 22

- Control cabinet: zone NEX

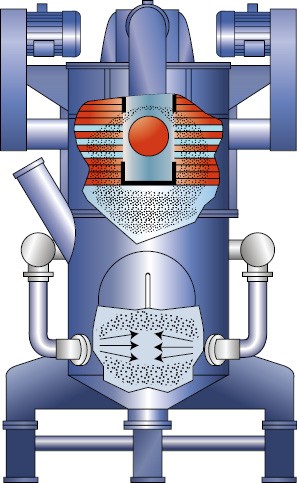

Fig.1 Fluidized bed opposed jet mill 400/1 AFG

The end products range between 10 and 40 µm in size and are free from oversized particles. The products are extremely homogeneous and display excellent suspension properties. The problem common when mechanical impact mills are used, i.e. the spalling-off of deposits, is unknown with fluidized bed opposed jet mills. This means that elaborate and expensive safety screening steps are no longer required in modern pesticides production systems configured with fluidized bed opposed jet mills. The AFG is capable of grinding complex pesticides formulations with active substance contents of up to 80%. The temperature rise in the AFG during grinding is negligible, meaning that even products with low melting points can be processed without problem. In special cases, it is even possible to grind pure active substances with the AFG. This type of processing has the big advantage that the carrier substances, which are already of end-product fineness, do not need to be passed through the mill system, but are rather mixed in at the end of the process.

The impact mills that were often employed in the past for grinding pesticides are much less suitable because of the temperature rise during grinding.

Fluidized bed opposed jet mill AFG

Machine with horizontal nozzle arrangement. -The AFG standard system for the production of pesticides.

Fluidized bed opposed jet mill AFG-R

Machine with 3-D nozzle arrangement and an additional nozzle at the bottom.

Advantage: practically no residues in the grinding chamber when emptying the machine.

Fig.2 Schematic figure of AFG with single classifying wheel

Fig.3 Schematic figure of AFG with multi classifying wheel

Related equipments

Feel free to contact us. if you have any questions or concerns.