- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Aluminum Powder (Flake) Paint

Aluminum Powder (Flake) Paint

Summary

Aluminum is very common metallic material with the characteristics of light, low cost and tough. However, powdery aluminum gives high risk of explosion, therefore utmost care is required for process designing. Powdery aluminum particles are used for pigment for decorative purpose to give shining effect in the metallic paint. They are more and more applied in automobile exterior and electric appliances. Aluminum pigment mixed with paint improves the weatherability protecting paints from heat and corrosion. Therefore, it takes an important role in the paint industry.

Contents

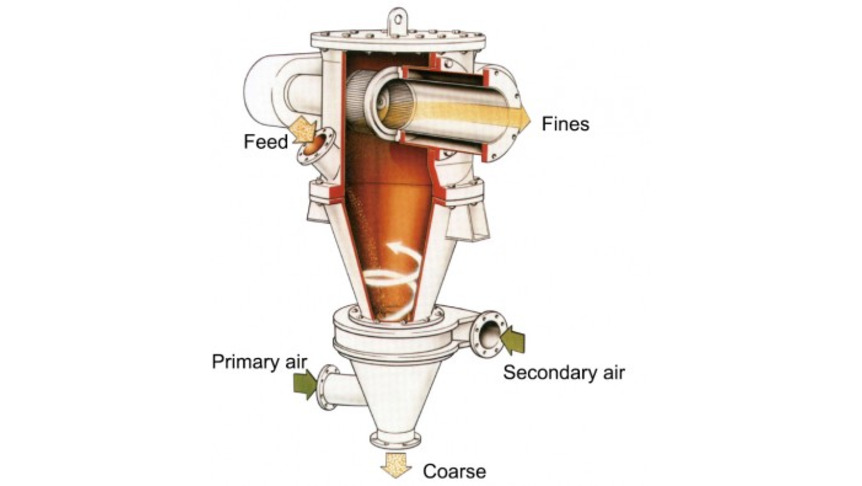

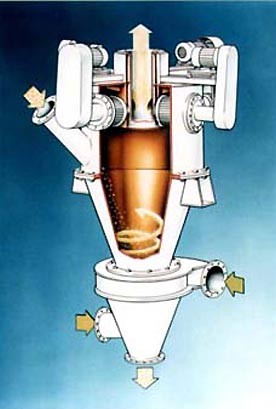

Aluminum fine particles made by atomization consist of a few μm to 100 μm sizes. Aluminum powders in the metallic paints are generally manufactured by classifying the atomized particles. The classified fines are flattened by wet ball mill for the flaky product of 10 μm diameter with 0.5 μm thickness. The flakes in the paint are arrayed on the paint film (leafing), which function to avoid intrusion of moisture and corrosive contents across the film and ensure uniform shine over the surface. To reduce diffused reflection high and ensure high shines, the flake is required to be uniform particle size distribution. Therefore the classifying process is very important to unify the size of the aluminum fine particles. For the classification process of the removal of fines and coarse particles, use of air classifier is common. However, when the classifier wheel size becomes large, available cut point becomes coarse due to structural reason and fines yield would be reduced. In case that very fine particle sizes are required, it is difficult to adopt large sized classifier models.

Our multi-wheel Turboplex (Fig.2) solves this problem by providing multiple small wheels in one classifier. This type of Turboplex enables to classify aluminum fine powders at large capacity. Therefore, it is adopted in aluminum pasting process worldwide.

The system with the online particle size analyzer (Fig.3) measures the particle size in process line on a real time basis; Intellisizer. In-line and on real-time measurement minimize the time lug of process evaluation and the risk of oxidization/explosion caused by sampling. Aluminum fine particles have high risk of dust explosion. To minimize the possibility of the explosion, it is required to have the system to suppress oxygen level in the process. On base of the technology and experiences, multi-rotor type Turboplex combined with nitrogen circulation system has been established for safe and economical classification systems.

Fig.1 Example of metallic paints

Fig.2 Turboplex

Fig.3 Online PSD measuring instrument Intellisizer XI

Related equipments

Feel free to contact us. if you have any questions or concerns.